Steel wire rope rejection criteria

Discard the wire rope in accordance with current regulations or according to the manufacturers recommendations.

Only a qualified and experienced person should be responsible for discard.

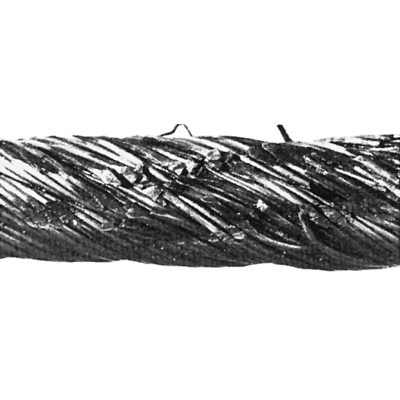

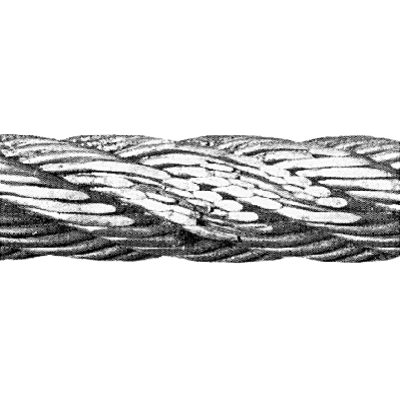

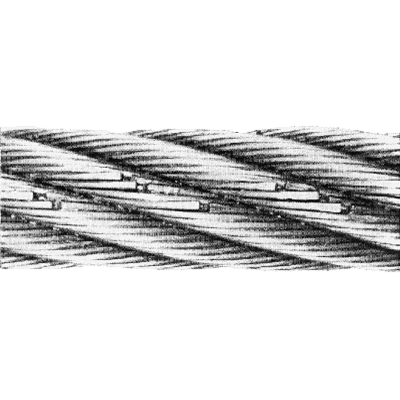

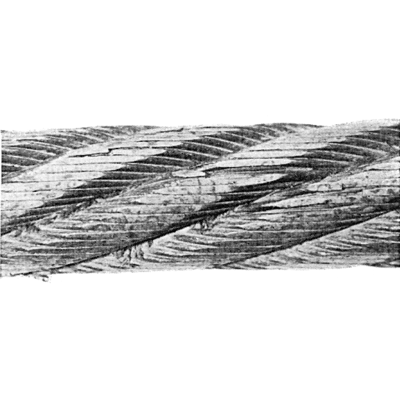

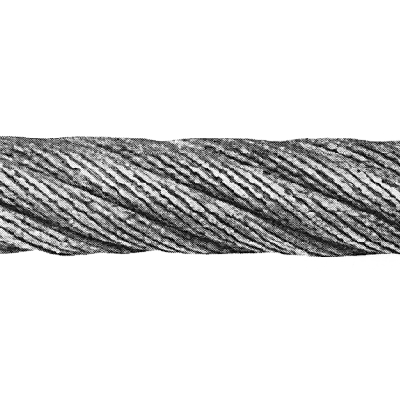

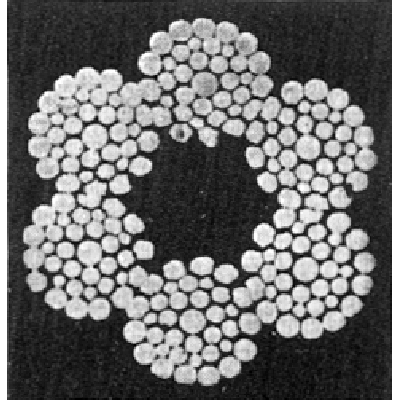

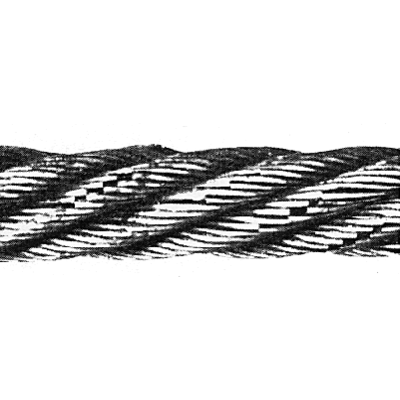

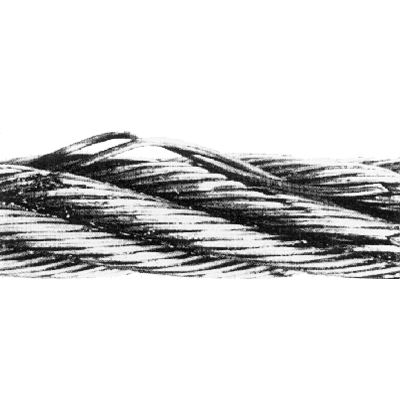

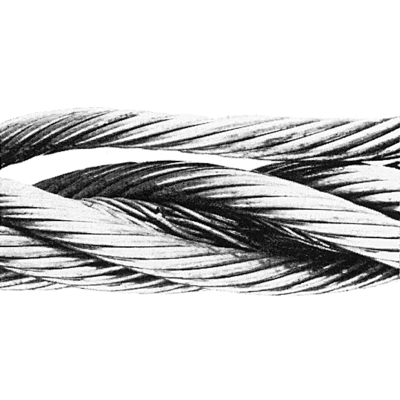

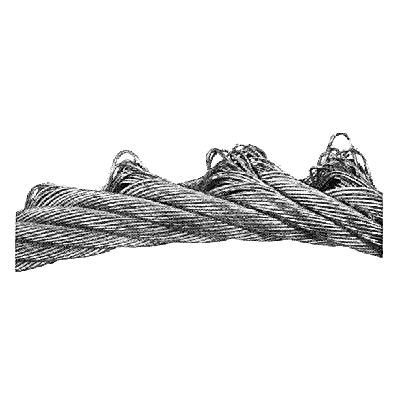

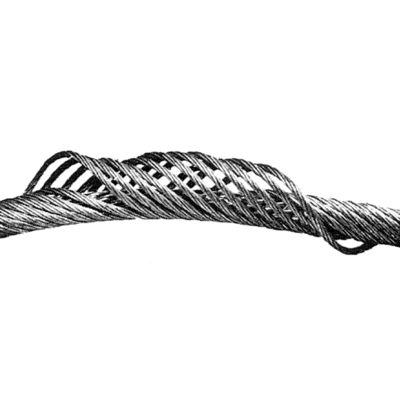

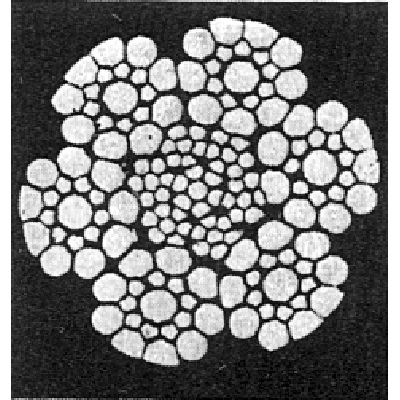

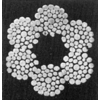

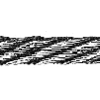

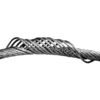

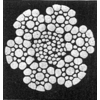

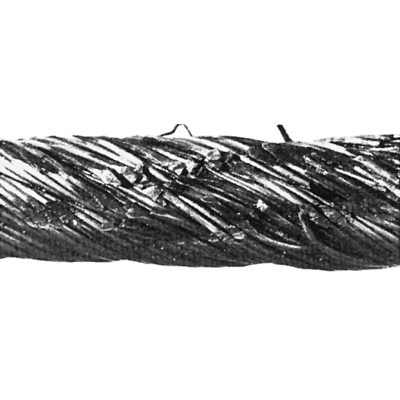

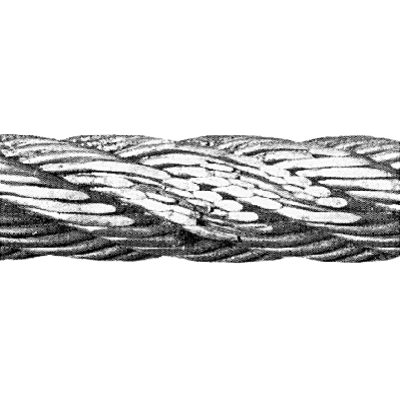

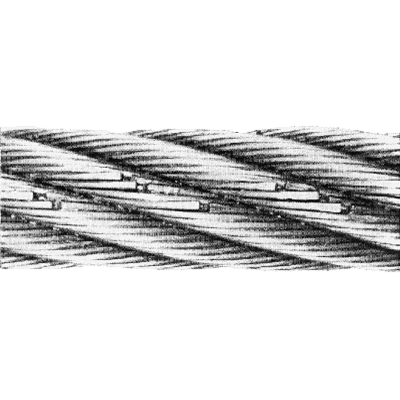

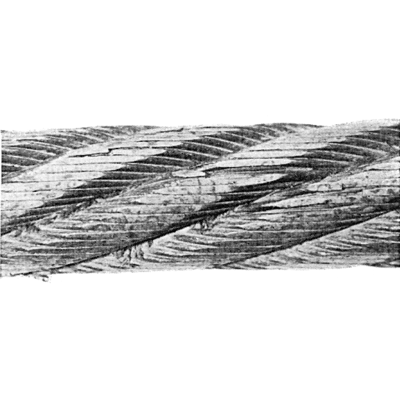

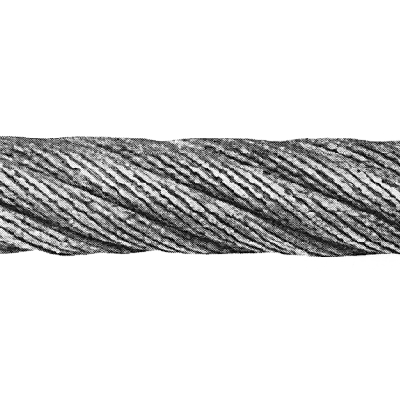

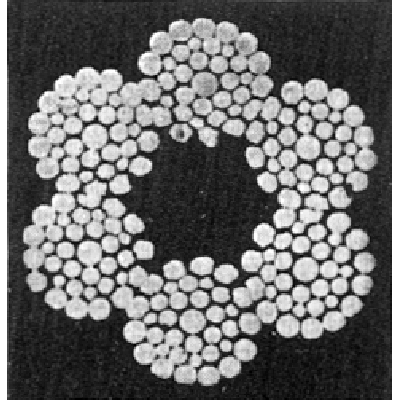

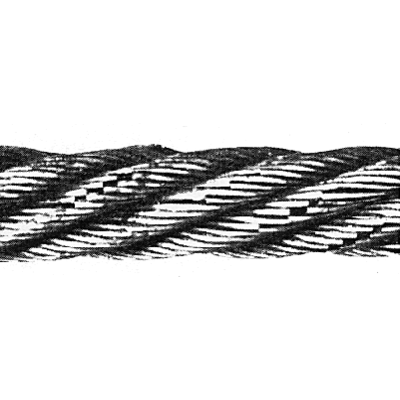

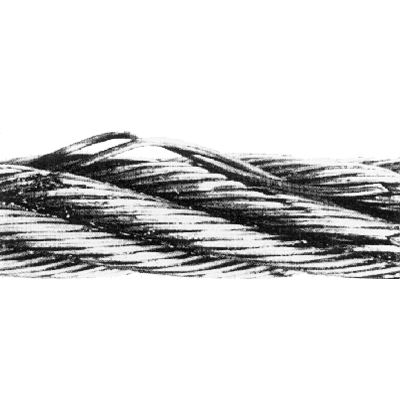

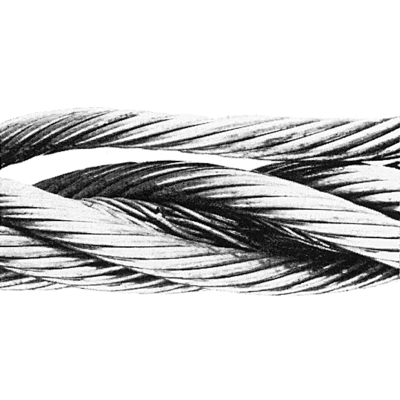

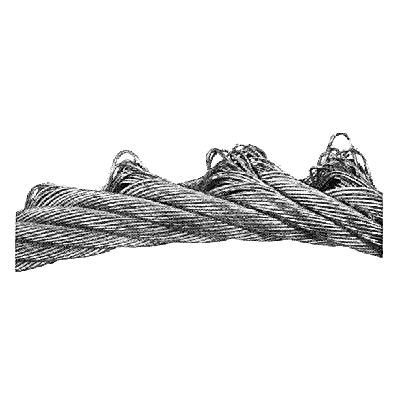

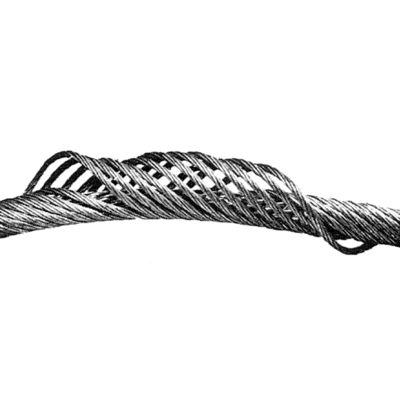

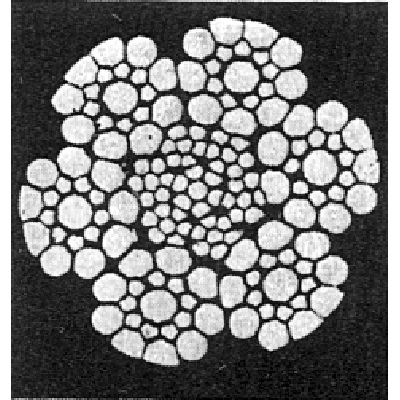

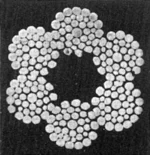

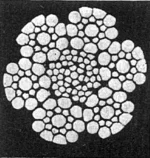

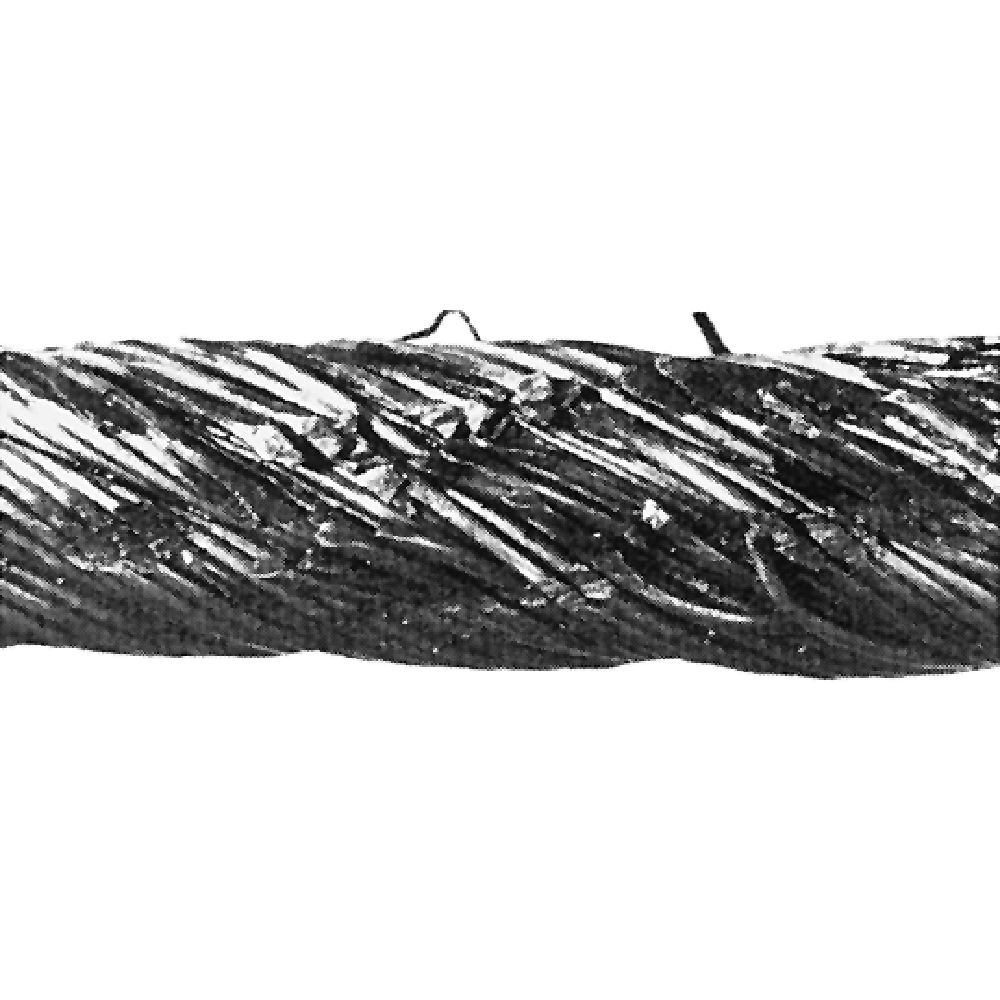

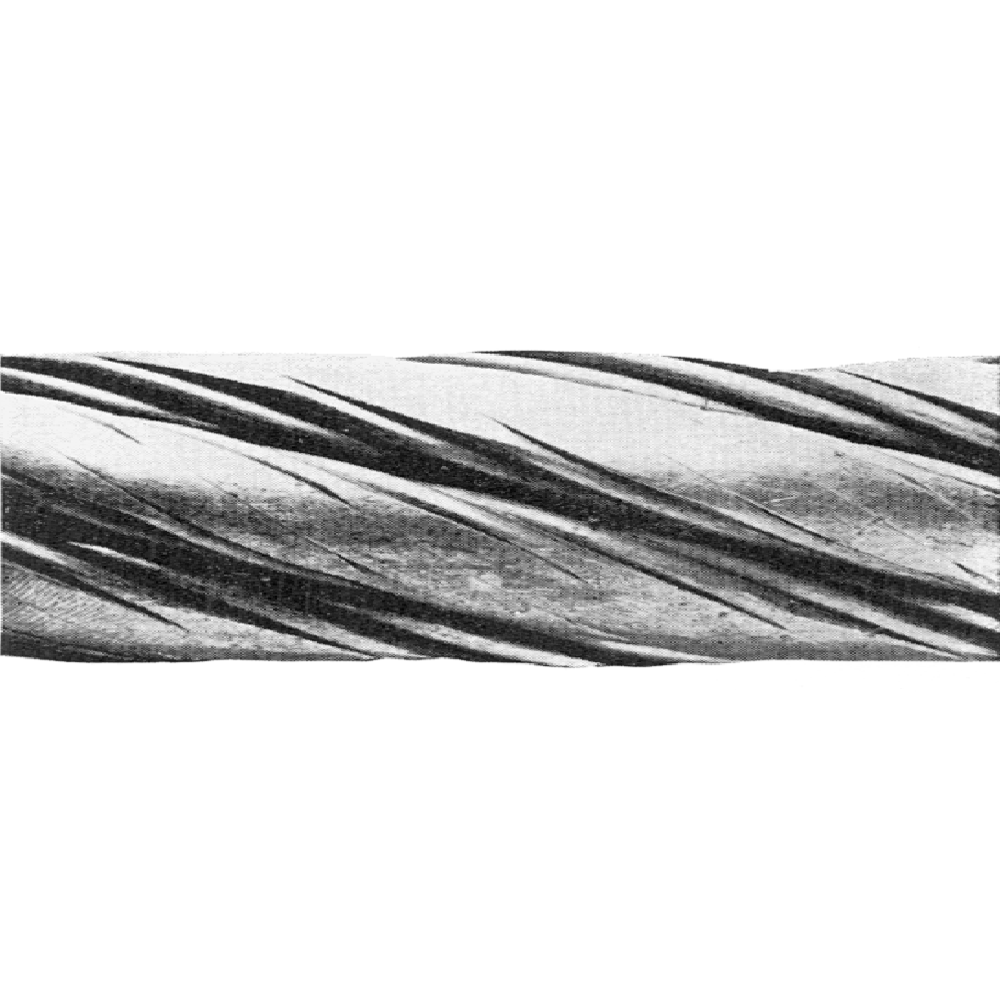

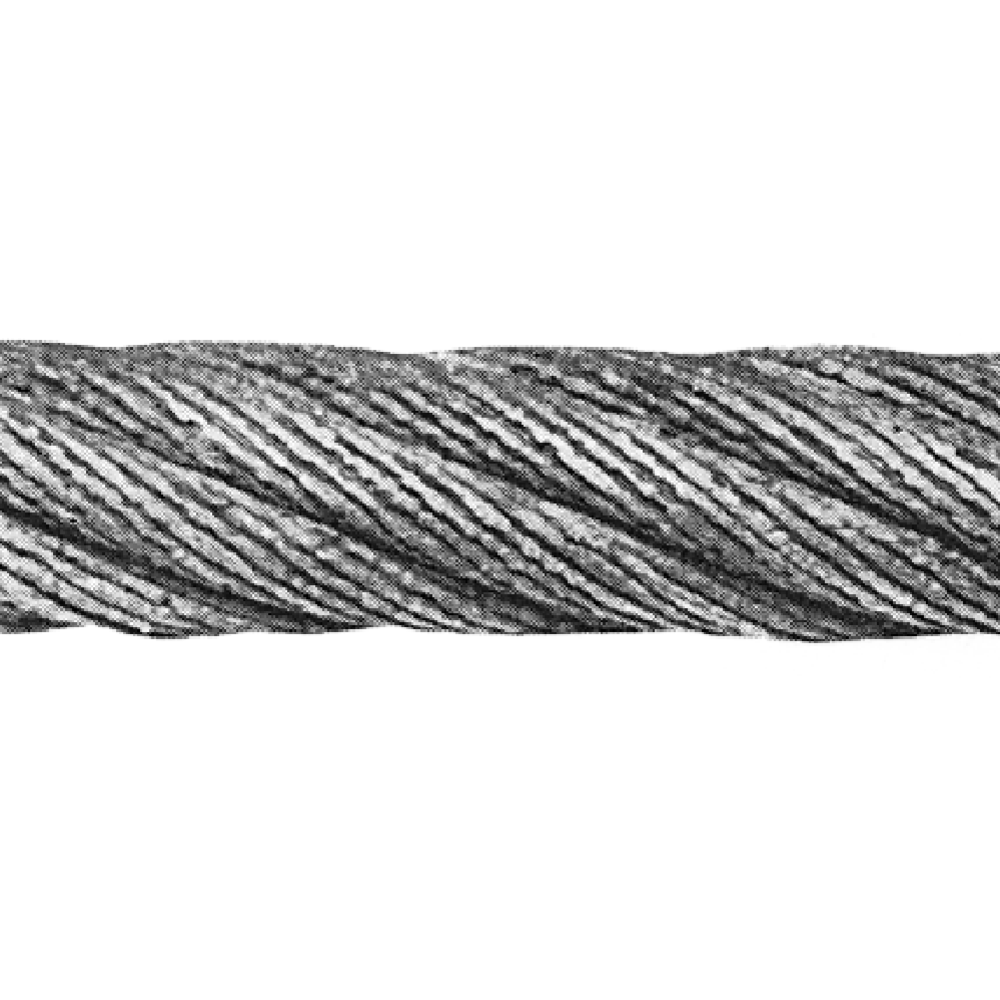

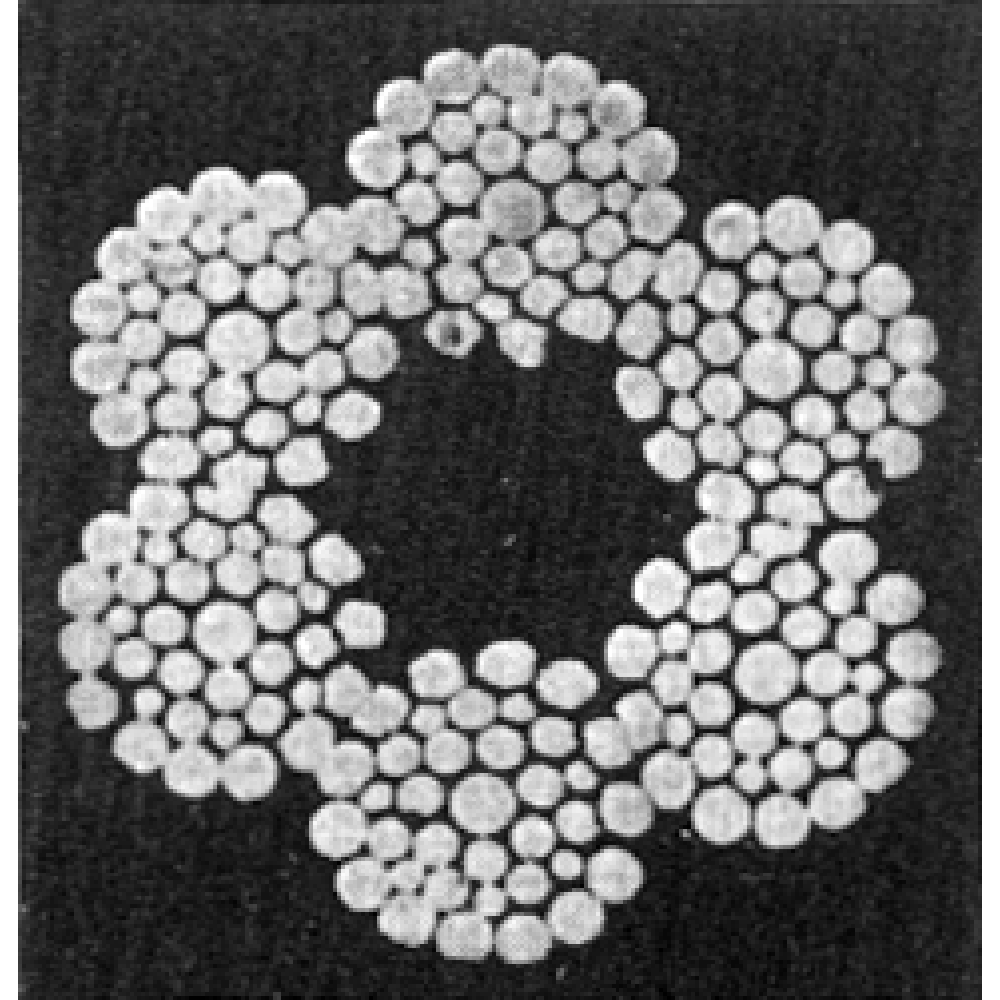

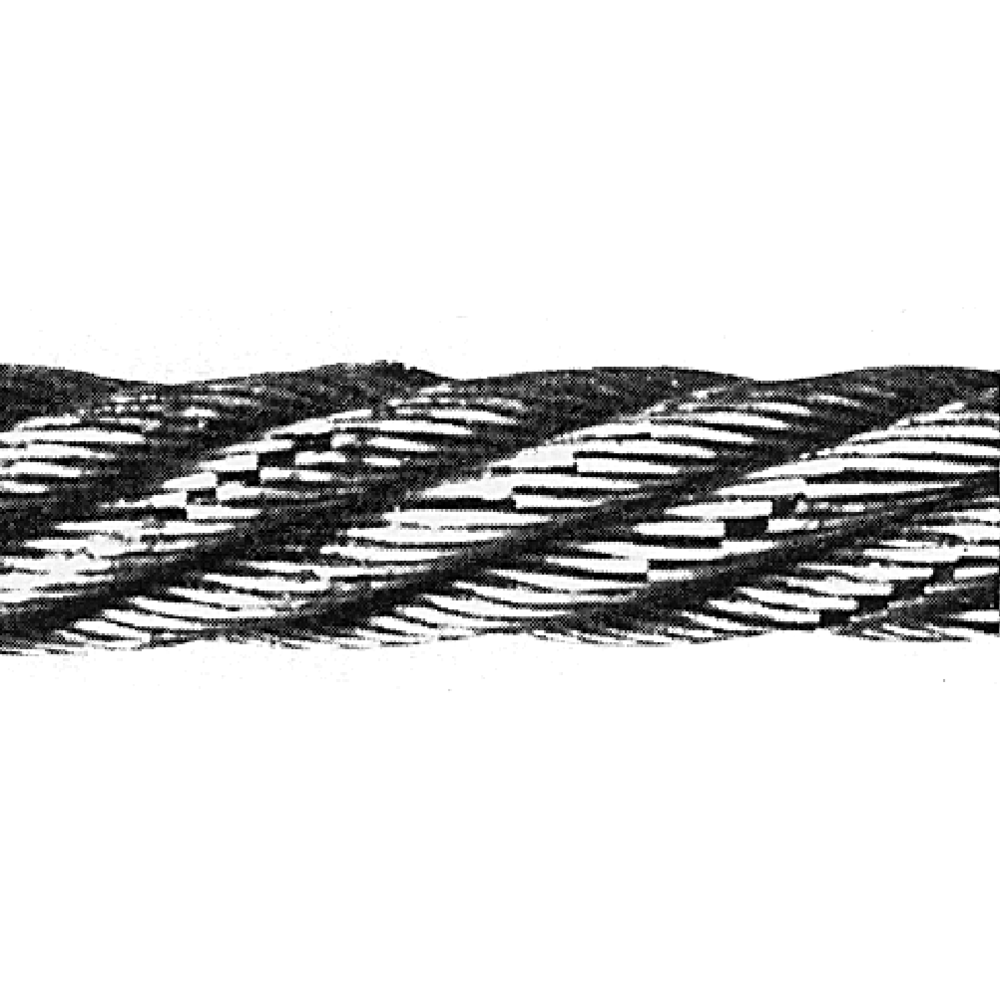

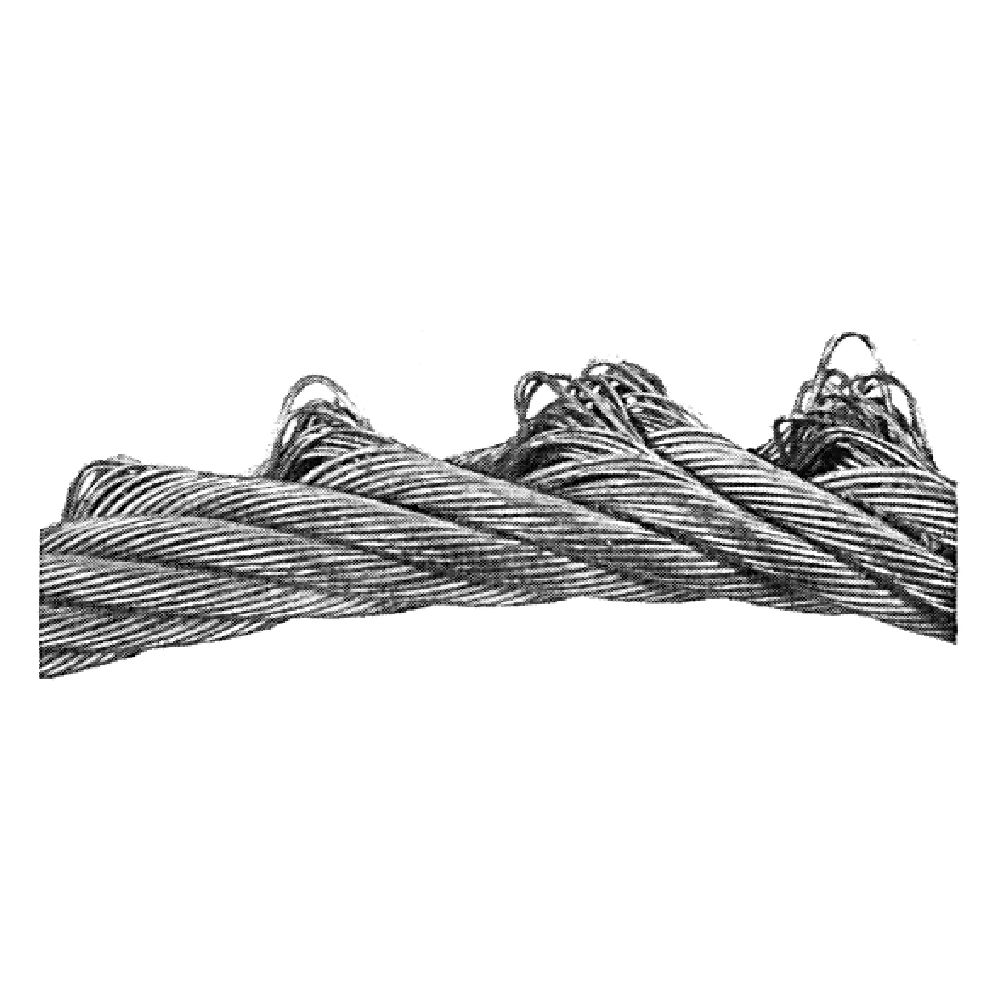

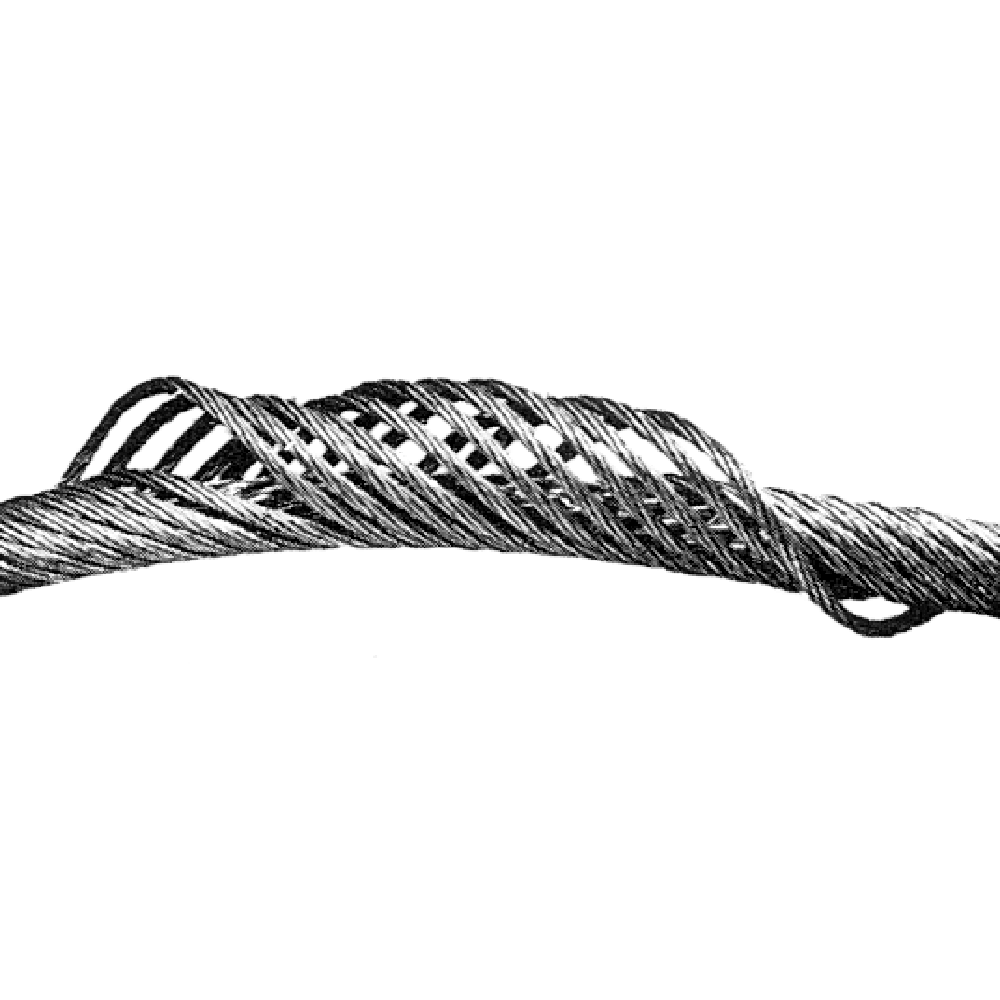

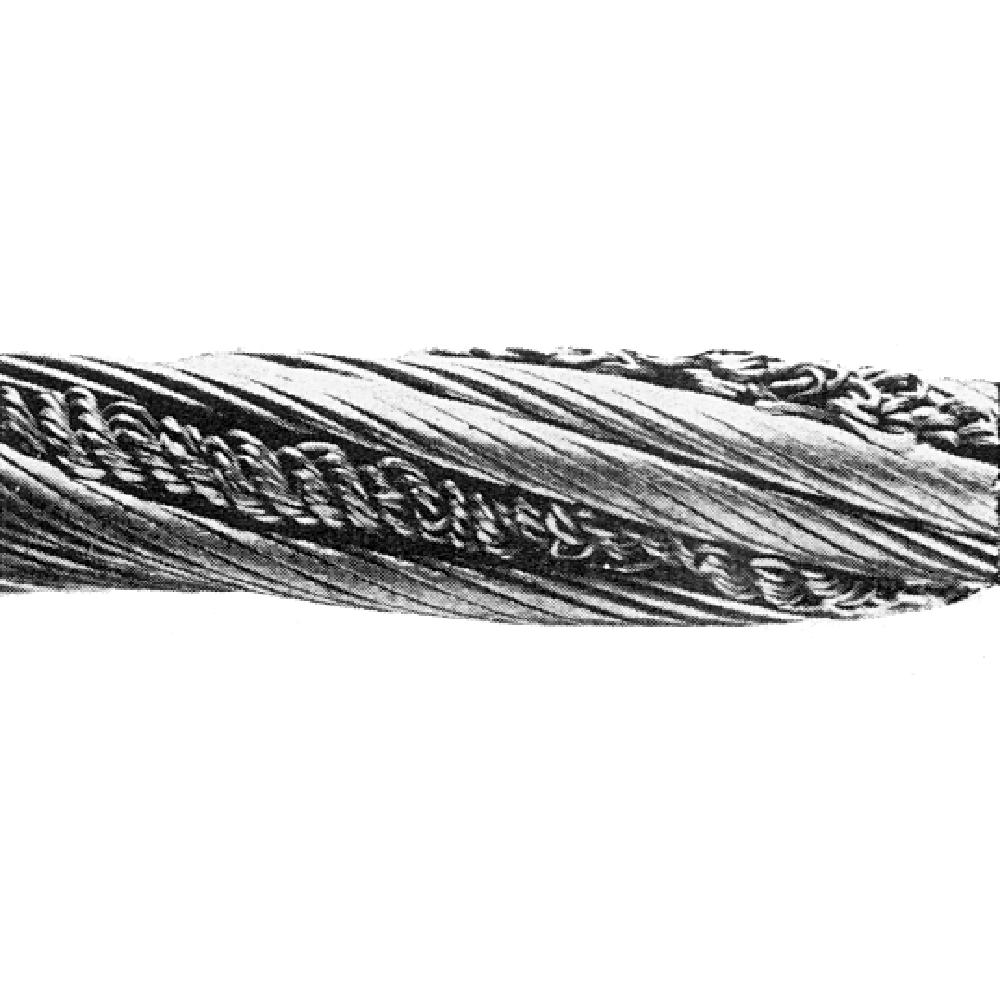

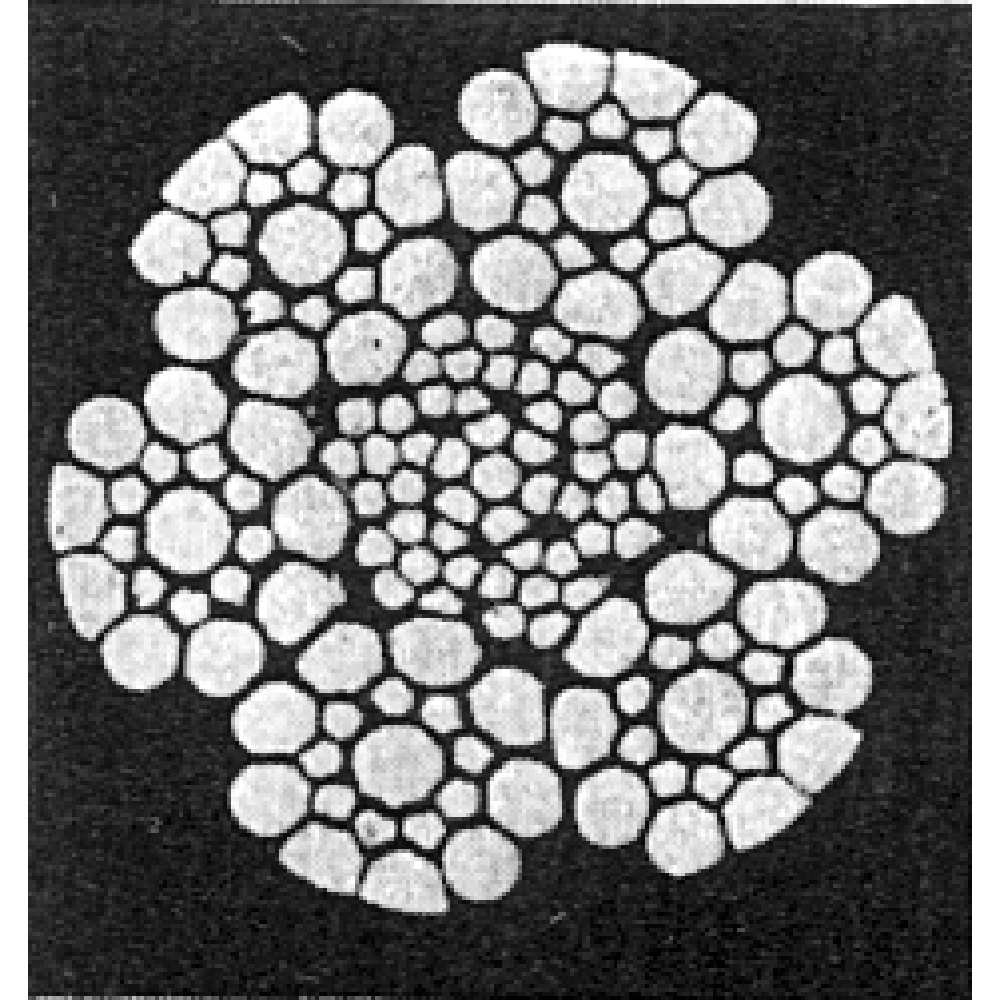

The pictures show typical examples of wire rope deterioration.

WARNING! Failure to take adequate precautions could result in injury.

| Rope category number |

Number of load-bearing wires in the outer layer of strands in the rope a

|

Number of visible brokenb outer wires over a length of: | |||||

|---|---|---|---|---|---|---|---|

| Section of rope working in steel sheaves and/or spooling on a single-layer drum | Sections of rope spooling on a multi-layer drum c | ||||||

| Classed M1 to M4 or class unknown d | All classes | ||||||

| Ordinary lay | Lang lay | Ordinary and Lang lay | |||||

| RCN | n | 6de | 30de | 6de | 30de | 6de | 30de |

| 1 | n ≤ 50 | 2 | 4 | 1 | 2 | 4 | 8 |

| 2 | 51 ≤ n ≤ 75 | 3 | 6 | 2 | 3 | 6 | 12 |

| 3 | 76 ≤ n ≤ 100 | 4 | 8 | 2 | 4 | 8 | 16 |

| 4 | 101 ≤ n ≤ 120 | 5 | 10 | 2 | 5 | 10 | 20 |

| 5 | 121 ≤ n ≤ 140 | 6 | 11 | 3 | 6 | 12 | 22 |

| 6 | 141 ≤ n ≤ 160 | 6 | 13 | 3 | 6 | 12 | 26 |

| 7 | 161 ≤ n ≤ 180 | 7 | 14 | 4 | 7 | 14 | 28 |

| 8 | 181 ≤ n ≤ 200 | 8 | 16 | 4 | 8 | 16 | 32 |

| 9 | 201 ≤ n ≤ 220 | 9 | 18 | 4 | 9 | 18 | 36 |

| 10 | 221 ≤ n ≤ 240 | 10 | 19 | 5 | 10 | 20 | 38 |

| 11 | 241 ≤ n ≤ 260 | 10 | 21 | 5 | 10 | 20 | 42 |

| 12 | 261 ≤ n ≤ 280 | 11 | 22 | 6 | 11 | 22 | 44 |

| 13 | 281 ≤ n ≤ 300 | 12 | 24 | 6 | 12 | 24 | 48 |

| Ropes having outer strands of Seal construction where the number of wires in each strand is 19 or less (e.g. 6 x 19 Seal) are placed in this table two rows above that row in which the construction would normally be placed based on the number of load bearing wires in the outer layer of strands. | |||||||

| a) Filler wires are not regarded as load-bearing wire and are not included in the values of n. b) A broken wire has two ends (counted as one wire) c) The values apply to deterioration that occurs at the cross-over zones and interference between wraps due to fleet angle effect. d) Twice the number of broken wires listed may be applied to ropes on mechanisms whose classification is known to be M5 to M8. e) d= nominal diameter of rope. |

|||||||