How to choose Steel Wire Rope?

Answer the questions and choose correct steel wire rope

When ordering steel wire rope, specify type, construction, dimension and length. Follow the machine manufacturers recommendations and make sure that the equipment has the right machine group/grade.

WARNING! The Wrong choice of steel wire rope can cause reduced working life, failure of the rope and/or damage of equipment.

The following questions can help you to choose the right construction of rope. If you have conflicting answers, you should choose the most frequent alternative. Putting together the ten answers will help to choose the optimum rope construction, but other questions and/or considerations can sometimes lead to another rope construction. For further advice, please contact CERTEX.

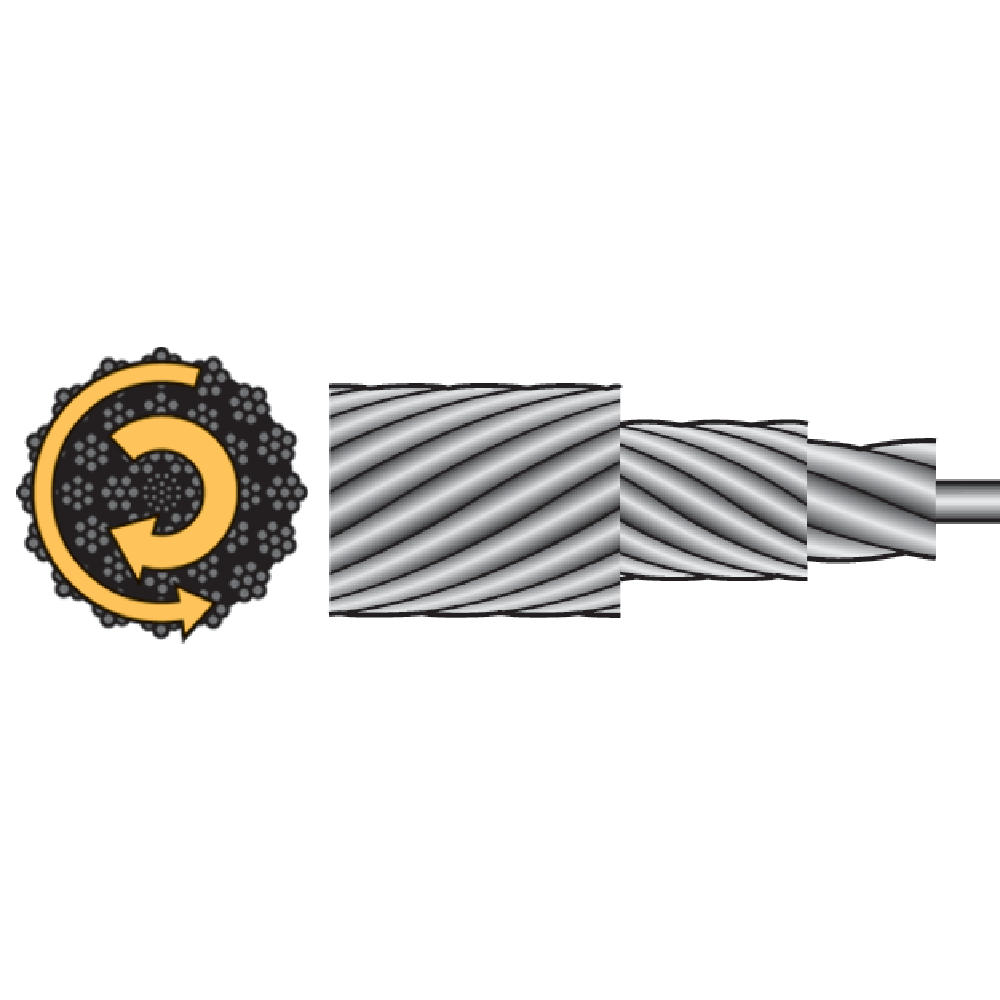

Tērauda troses ar pretrotācijas īpašībām

Lai sasniegtu pēc iespejas mazāku rotācijas tendenci pie lieliem pacelšanas augstumiem, tiek lietotas troses ar pretrotācijas īpašībām.

Troses ar pretrotācijas īpašībām ir veidotas no vairākiem vijumu slāņiem. Katrs slānis ir savīts uz pretējo pusi tādā veidā, lai griezes moments starp slāņiem izlīdzinātos.

| Question | Yes | Yes and No | No | |

|---|---|---|---|---|

| 1 | "Rotation resistance" demanded? | "Rotation resistant" rope | "Rotation resistant" rope | 6/8/9/10-strand rope |

| 2 | High breaking load demanded? | Special rope, compacted | Rope with steel core | --- |

| 3 | Lots of bending? | Multistrand rope with small outer wires | Multistrand rope with small outer wires | --- |

| 4 | Large outer wear? | Rope with large outer wires | Rope with large outer wires | --- |

| 5 | Coiled in many layers? | Lang's lay rope, compacted | --- | Ordinary hand lay rope |

| 6 | Risk of deformation- damage? | Rope with plastic encapsulated core | Rope with plastic encapsulated core | --- |

| 7 | Large rope guide angles? | Rope with plastic encapsulated core | Rope with plastic encapsulated core | --- |

| 8 | Left groove drum? | Right hand lay | --- | Left hand lay |

| 9 | Left drawn rope guide? | Right hand lay | --- | Left hand lay |

| 10 | Corrosive environment? | Galvanised/stainless rope | Galvanised/stainless rope |

Bright/galvanised rope |

High performance steel wire ropes

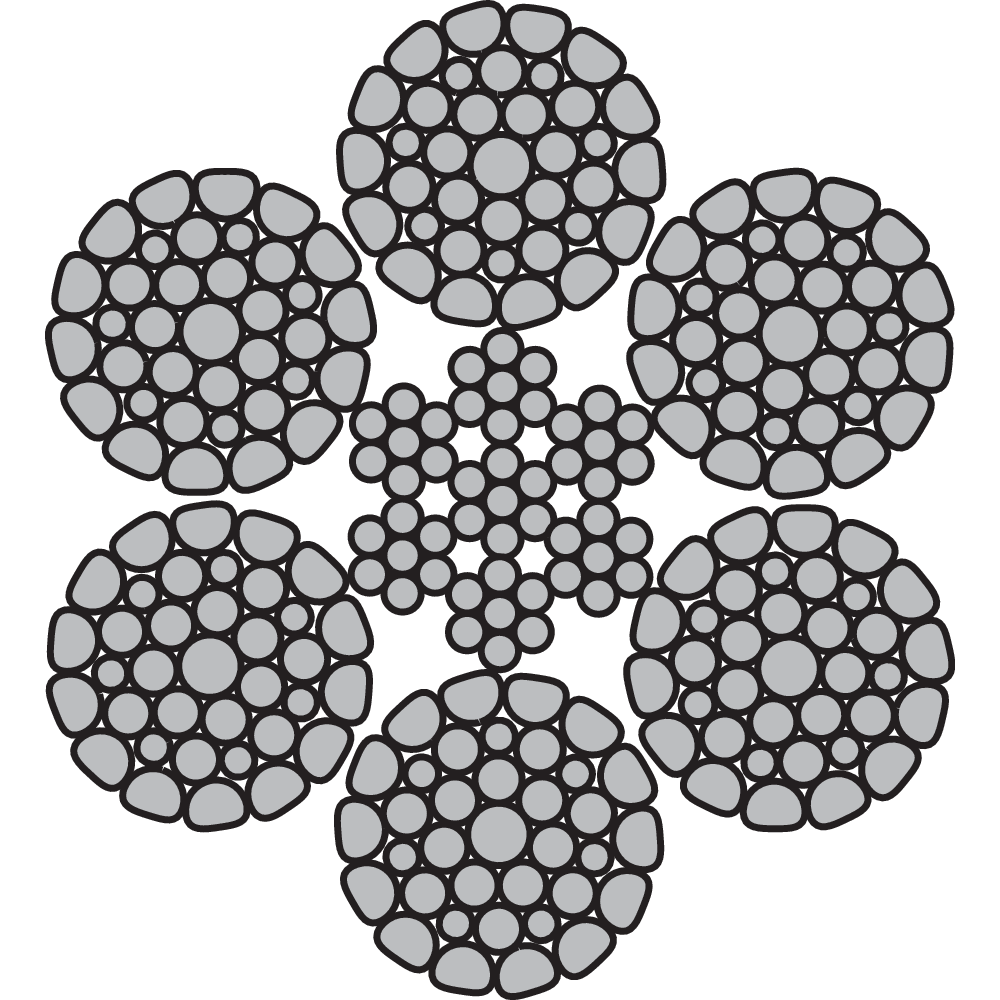

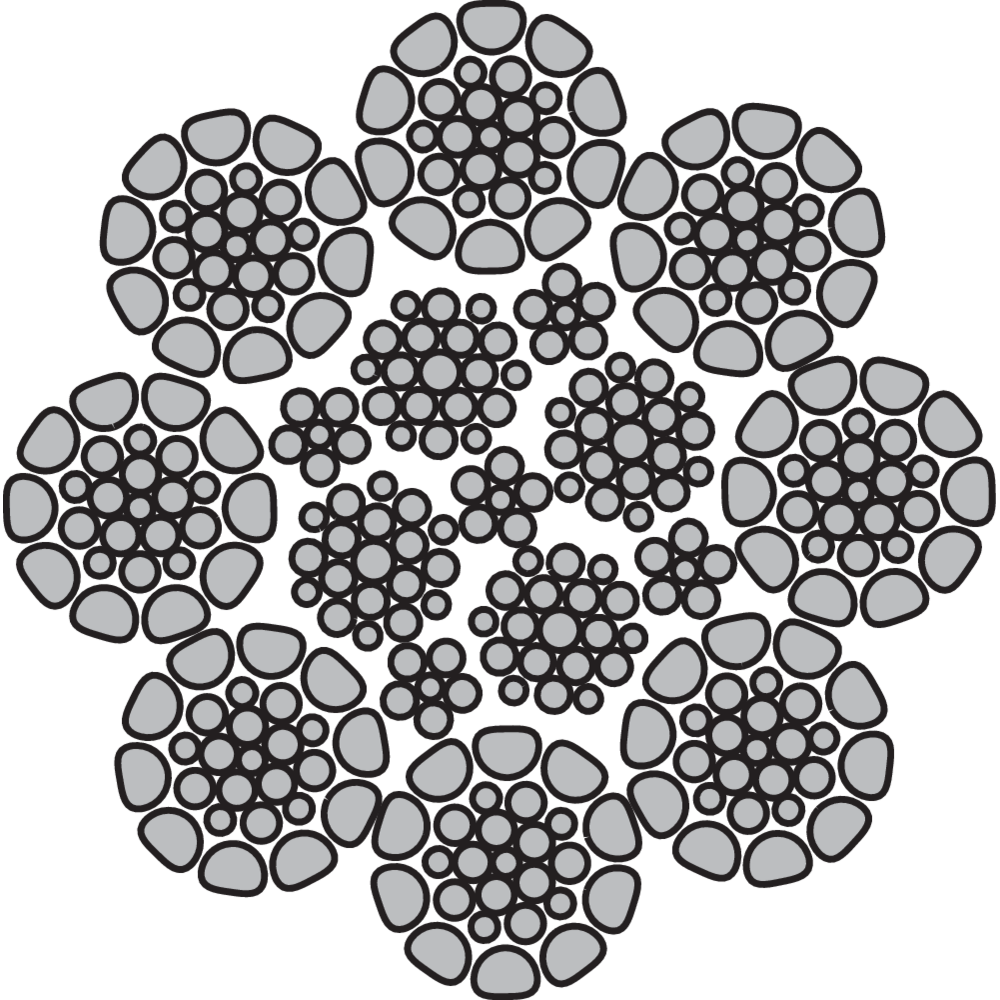

Demands for longer operation life and higher breaking loads have contributed to the development of "special wire ropes". These are to be used in demanding and tough environments when the ropes are used intensively.

The special wire ropes are often manufactured with high tensile wires and the strands are in many cases compacted to give a larger steel area and consequently a higher breaking load. This results in an increased working load for a specific rope diameter. Compacting of the rope also results in longer life and therefore a lower life cost.

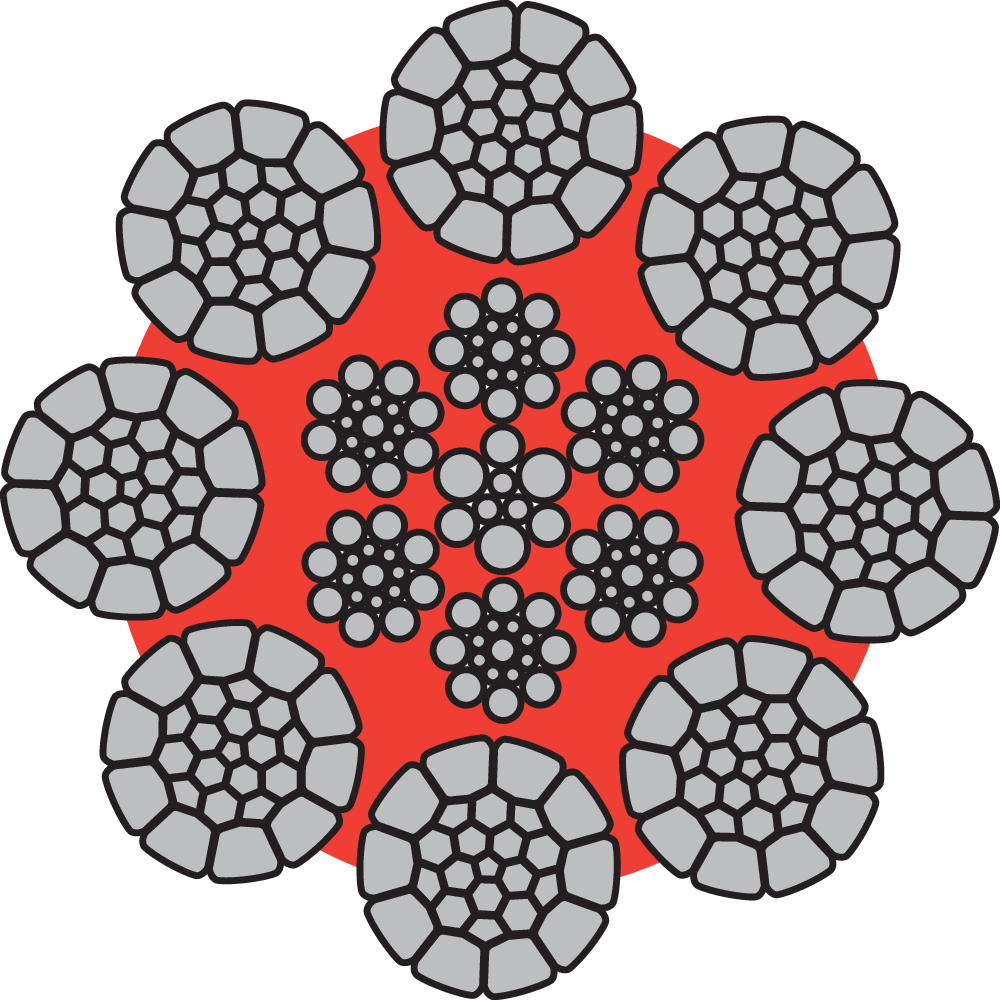

Some areas of use demand wire ropes with better stability and extra low inner friction. For that purpose ropes are manufactured with a plastic coated steel core.

Special wire ropes can be double parallel which means that both wires and strands lay parallel to each other. This prevents wire cross over which can lead to wire indentations. Special wire ropes have a few things in common: less outer and inner friction, narrow tolerances, more flexible, more rounded and a larger contact surface against sheaves and drums. This results in a longer life in tough working conditions.

Minimum and calculated breaking load

The Minimum breaking force (minimum breaking load), in kilonewtons, is the lowest breaking strain of the rope when tested to destruction.

The value calculated from the product of the sum of the crossectional metallic areas of all the individual wires in the rope and the tensile strength grade(s) of the wires. The total metallic area is directly proportional to the square of the nominal diameter of the rope. A standard spinning loss factor that results from the twisting of strands and wire is then applied.

Do you have any questions?

If you have any additional questions, please contact us and we will answer you.