How to install and use wire rope?

Steel wire rope packing

Wire rope is generally delivered in a coil, plywood or wooden reel. On the European mainland a cross reel is also common. Please specify packaging when ordering.

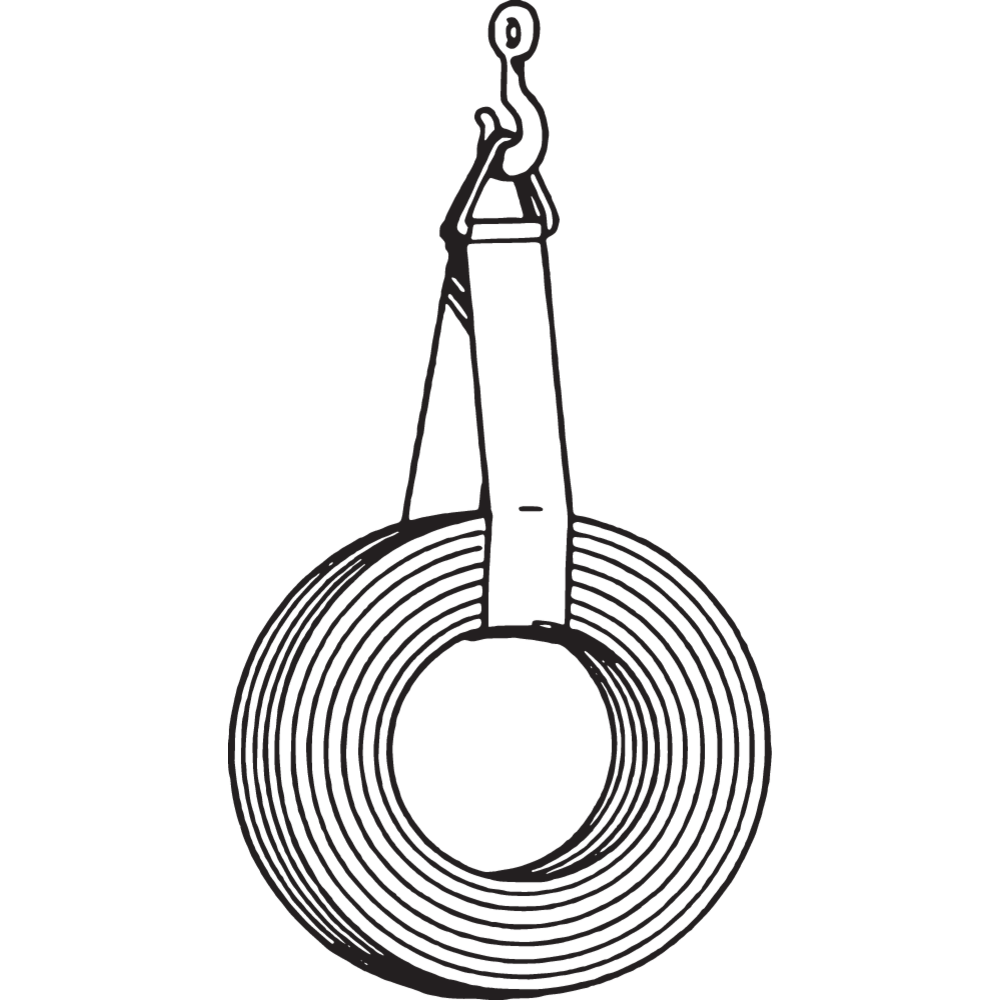

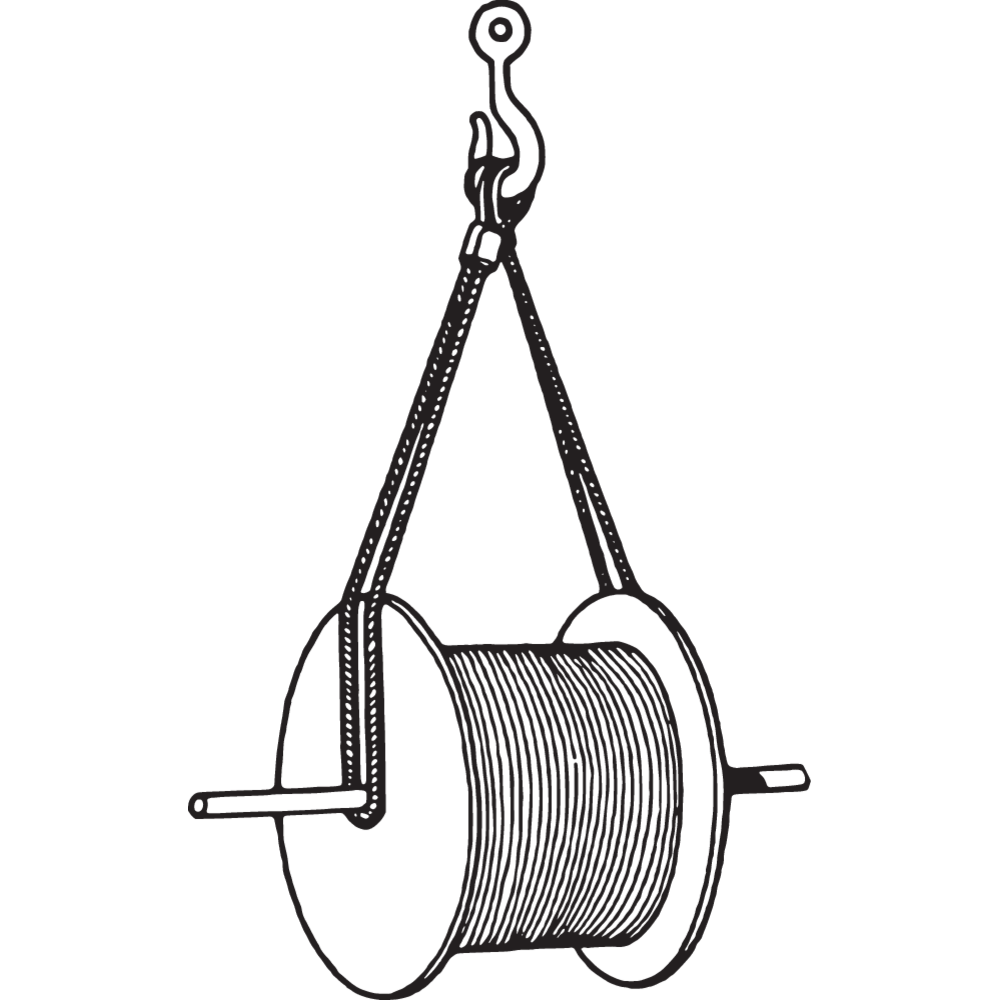

Safe lifting and handling

Ensure that the rope is not damaged by fork lifts or other handling equipment, by lifting or handling.

WARNING! Wrong handling/lifting can damage the rope.

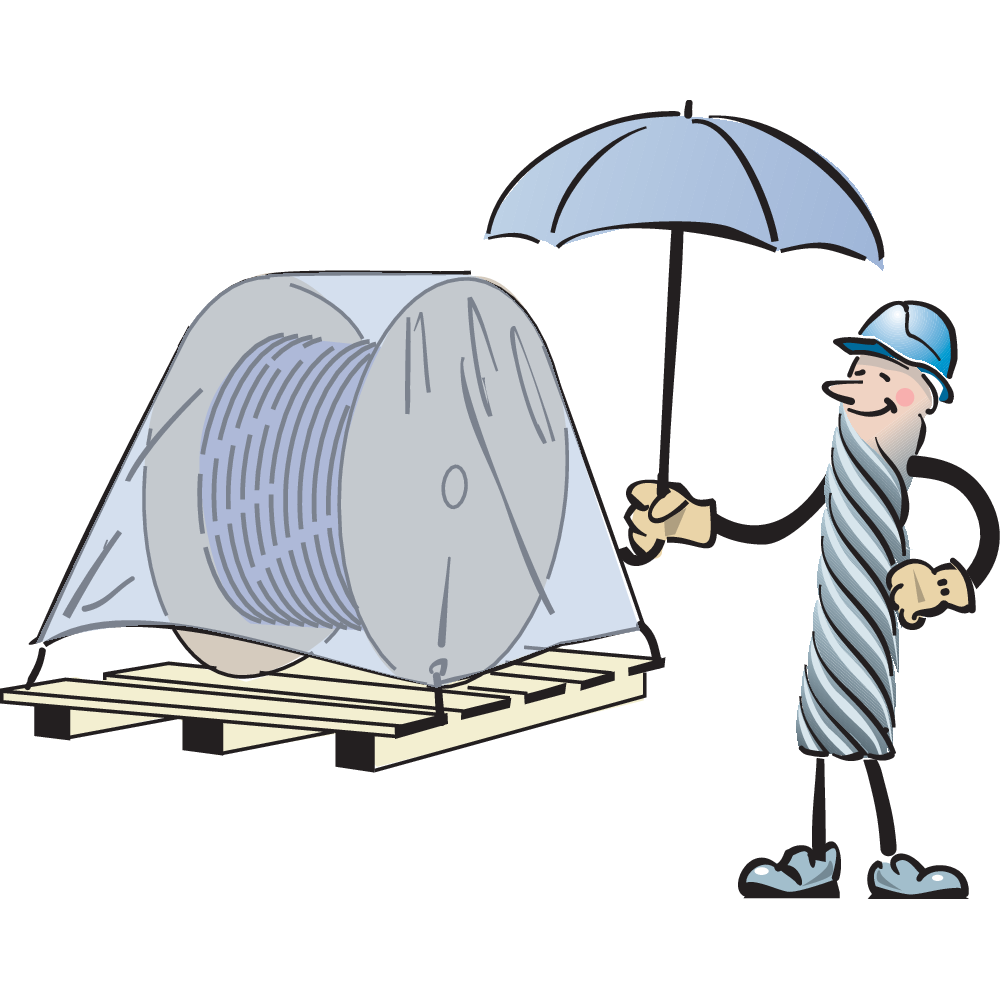

Storage requirements

Steel wire ropes shall be stored in a dry and well ventilated location. Cover with waterproof material for outside storage. Rotate the reel periodically during long periods of storage, particuarly in warm environments. The ropes shall be examined regularly and lubricated if necessary.

WARNING! Incorrect storing can cause damage to the wire rope. Never store the rope in an environment with large variations in temperature.

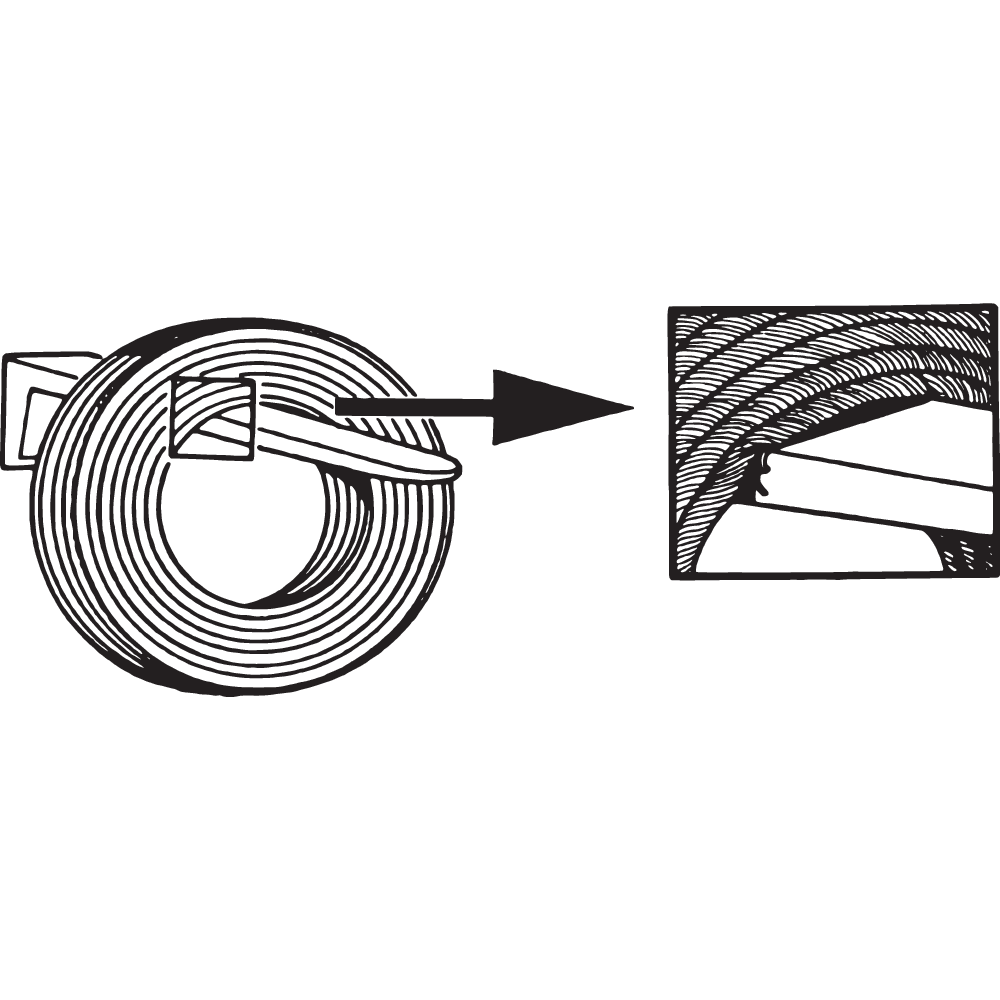

Coiling and winding

Wrong coiling can cause serious damage to the steel wire rope. Coil or wind according to the following:

- Reels should be rolled out or alternatively placed on a turnable centre.

- Cross reels and drums should be placed on a shaft that allows it to rotate.

- Wind and unwind the rope in the same direction.

- In some cases it may be necessary to brake the drum.

WARNING! Wrong "opening" of packing can cause serious injury to personnel, first ensure that the rope is under control.

Never pull a rope from a stationary reel or drum - due to the risk of kinking.

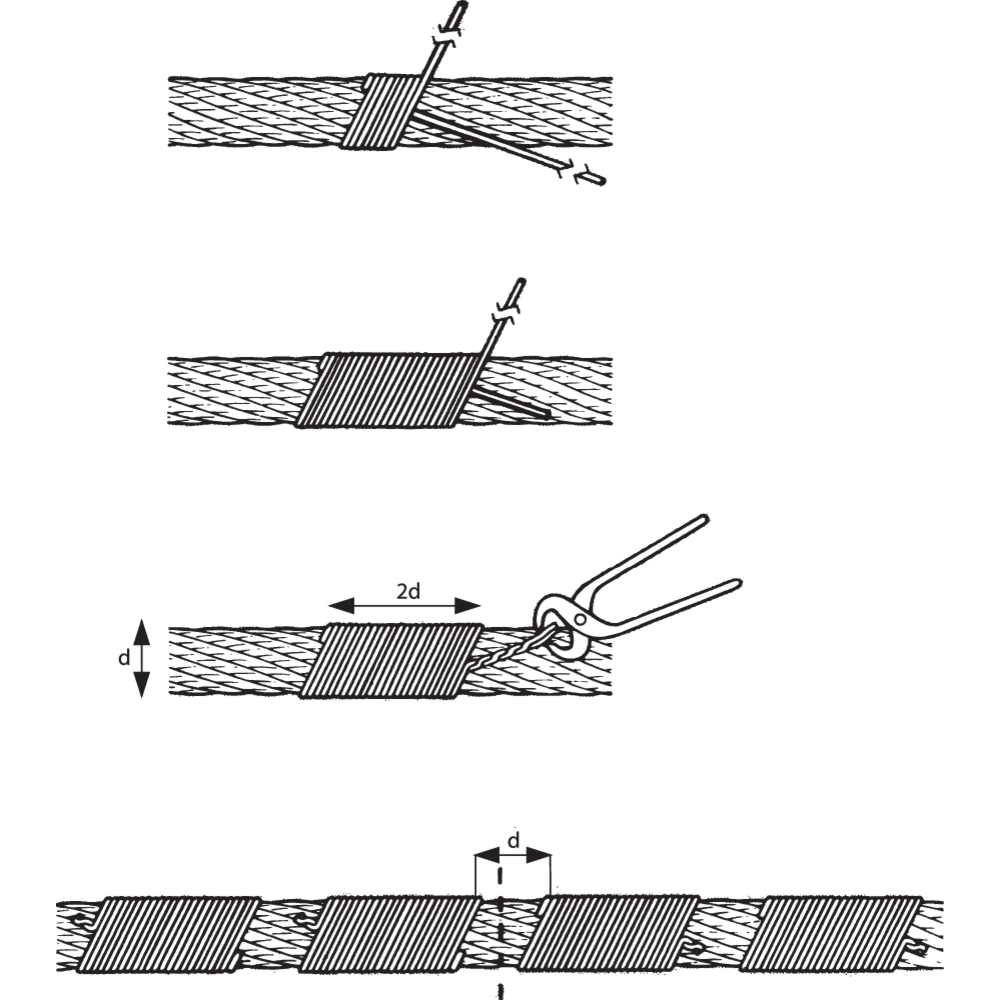

Incorrect cutting can cause damage to the rope

Usually ropes are supplied in cut lengths, with "tapered" ends made by annealing. If the rope is required to be cut during assembly the rope shall be seized each side of the cut, to prevent damage from opening strands and/or changing lay length.

One seizing either side of the cut is normally sufficient for preformed ropes. For "rotation resistant" and special wire ropes a minimum of two seizings each side of the cut will be necessary. The length of each seizing should be a minimum 2 x rope diameter.

Cutting should be made with a high speed abrasive disc cutter, cutting torch or other suitable mechanical or hydraulic shearing equipment.

After the rope has been cut the seizing should be left until all the wires are welded or otherwise secured.

WARNING! Incorrect cutting can cause damage to the rope. Be extra careful when cutting rotation resistant ropes.

Use safety goggles and other appropriate safety equipment when using a disc cutter or other mechanical or electrical devices.

Connection of the old and new rope

When installing a new rope a cable sock or alternatively a welded pad eye can be used as connection between the old and new rope.

Individual turn between two ropes when installing can be possible with a swivel, which avoids turn being transmitted from the "old" rope into the new rope.

WARNING! Always check that "rope torque" does not exist during installation. A cable sock or other connection should be equipped with a swivel.

![eye-sock [Converted]_225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11556/image-thumb__11556__general-base/eye-sock-converted-_225mm_2.b53a4296.png)

![eye-sock [Converted]_225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11556/image-thumb__11556__general-thumb/eye-sock-converted-_225mm_2.b26b9b83.png)

![eye-sock [Converted]_225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11556/image-thumb__11556__general-base/eye-sock-converted-_225mm_2.b53a4296.png)

The general condition of the drum

Check the general condition of the drum. If the drum is grooved, check the radius and pitch are compatible with the diameter of the new rope.

WARNING! The drum can in some cases cause damage to the rope and lead to early discard. If the drum diameter is too small this can cause permanent distortion to the rope which will cause to early discard of the rope.

![drum [new2]_225mm_Eng](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11561/image-thumb__11561__general-base/grooveprofile_drum.c99a90ff.png)

![drum [new2]_225mm_Eng](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11561/image-thumb__11561__general-thumb/grooveprofile_drum.2c3b1d48.png)

![drum [new2]_225mm_Eng](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11561/image-thumb__11561__general-base/grooveprofile_drum.c99a90ff.png)

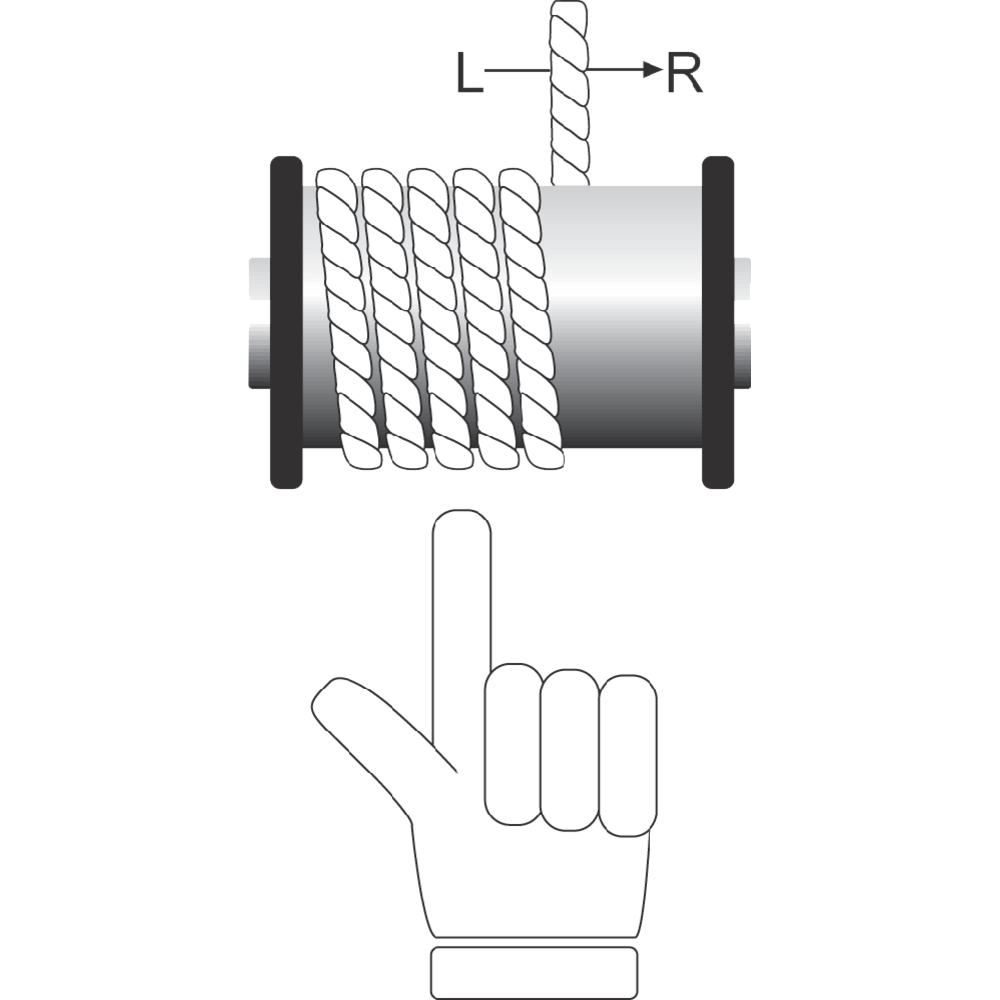

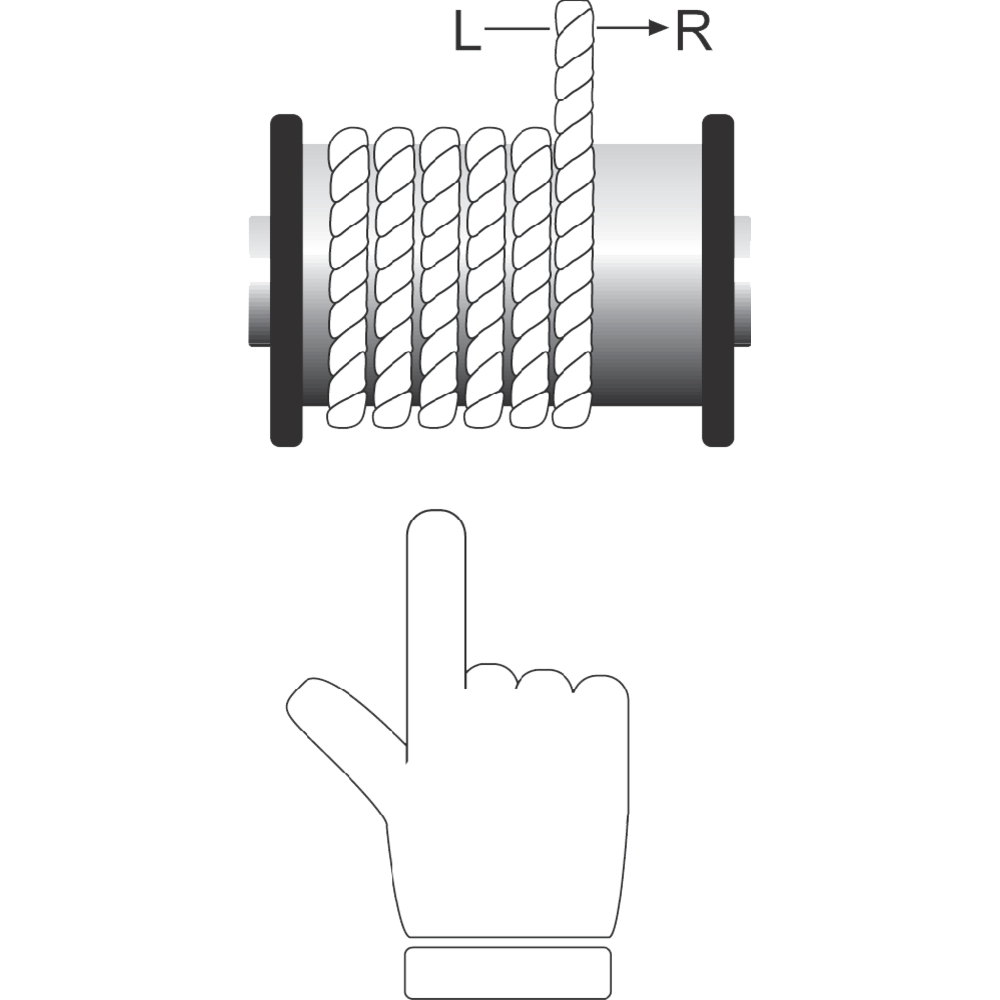

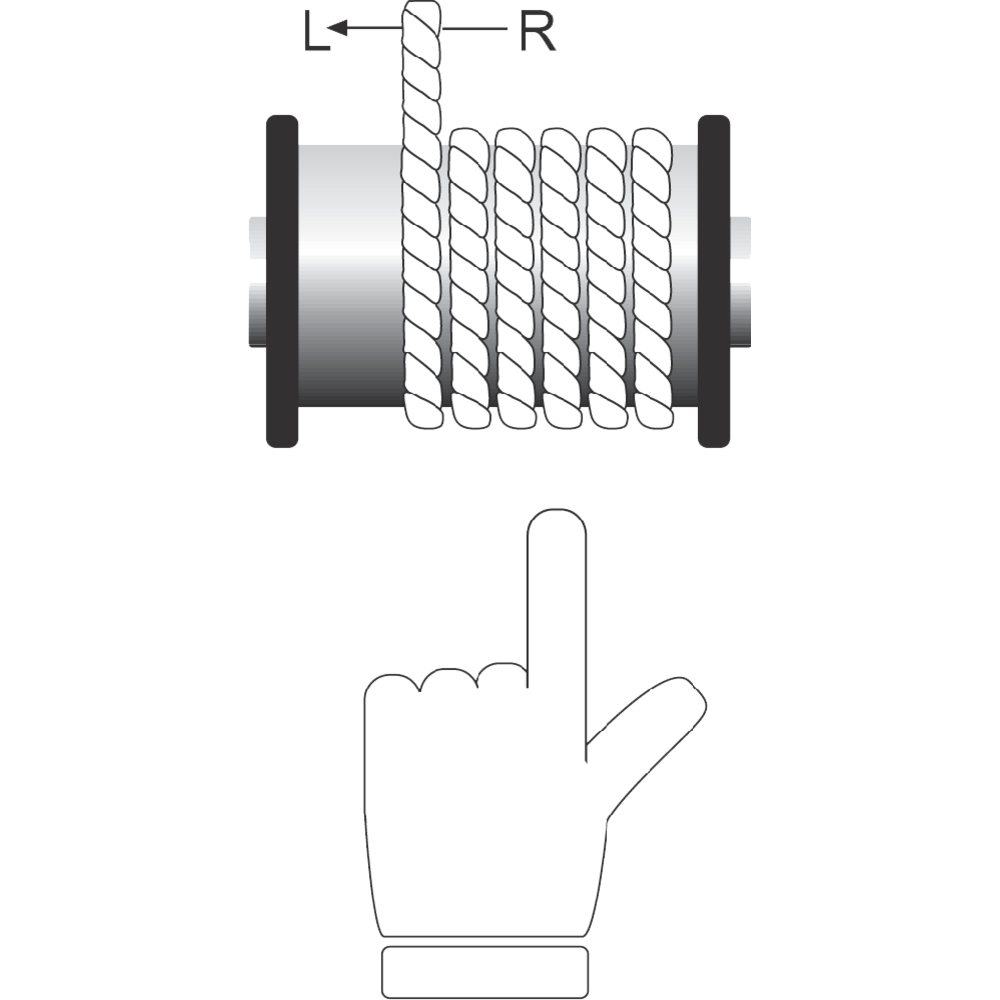

Coiling directions

The rotation direction and the attachment point of the rope determines whether right or left hand lay rope should be used. To determine the correct rope the following rule should be followed:

Right thread groove on the drum - left hand lay rope.

Left thread groove on the drum - right hand lay rope.

WARNING! Incorrect choice of lay can adversely affect rope performance.

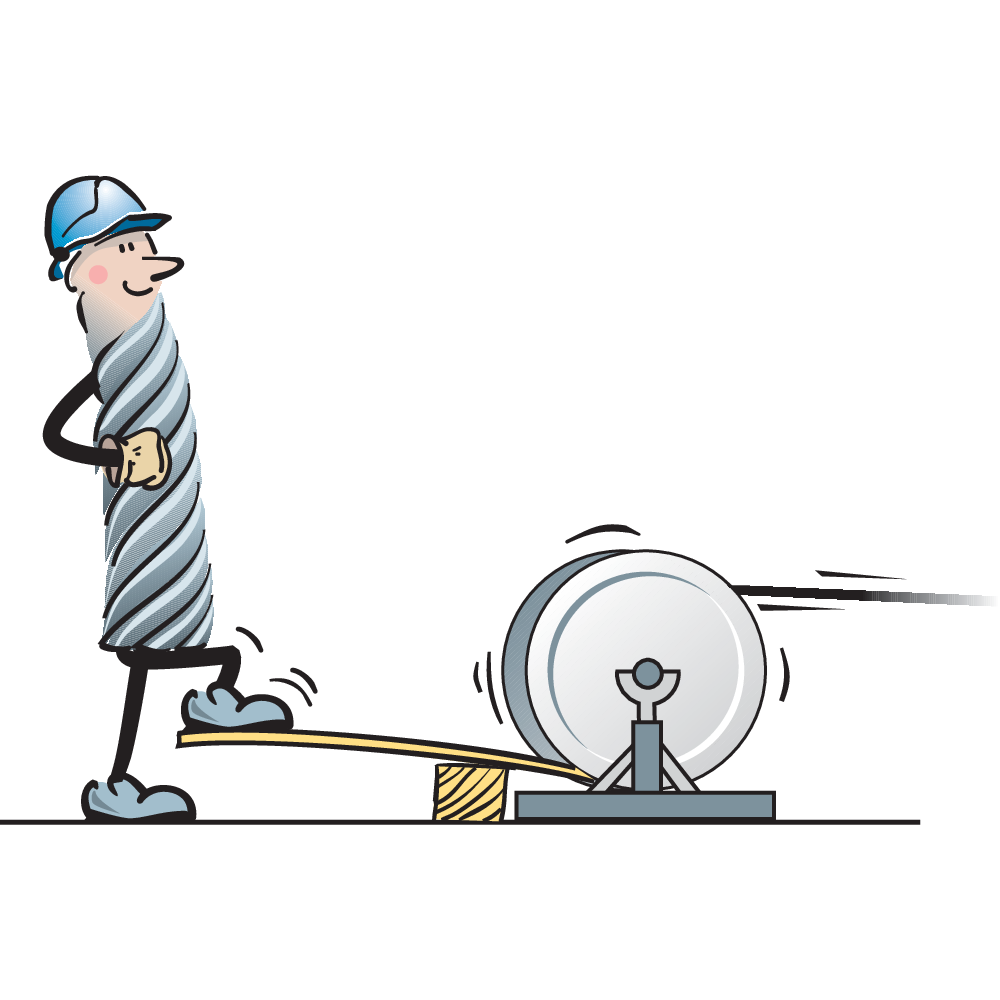

Pass a shaft through the reel and place the reel in a suitable stand which allows it to rotate and be braked to avoid over run during installation. Where multi-layer coiling is involved it may be necessary for the reel to be placed in equipment which has the capability of providing a back tension to the rope as it is being transferred from reel to drum. This is to ensure that the underlaying (and subsequent) laps are wound tightly on the drum.

WARNING! Incorrect coiling may cause severe damage to the wire rope as well as its performance.

Steel wire ropes winding in multiple layers

Multiple layers of wire on the drum can cause deformation (flattening, distortion etc) in the lower layers if the wrong rope construction is used and/or by incorrect winding.

![multiple-layers-[Converted][new]_225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11562/image-thumb__11562__general-base/multiple-layers--converted-new-_225mm_2.4c3c1997.png)

![multiple-layers-[Converted][new]_225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11562/image-thumb__11562__general-thumb/multiple-layers--converted-new-_225mm_2.87f8124b.png)

![multiple-layers-[Converted][new]_225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11562/image-thumb__11562__general-base/multiple-layers--converted-new-_225mm_2.4c3c1997.png)

Fleet angle can cause wear of the rope

Too large a fleet angle can cause excessive wear of the rope against the adjacent wrap on the drum. This can also lead to torsional problems.

![fleetangle[new]._225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11563/image-thumb__11563__general-base/seil_5.f92ce9c7.png)

![fleetangle[new]._225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11563/image-thumb__11563__general-thumb/seil_5.a5cb8c72.png)

![fleetangle[new]._225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11563/image-thumb__11563__general-base/seil_5.f92ce9c7.png)

Rope length calculation

The following formula gives an approximate indication of the length of a rope of a given diameter (d), which can be installed onto a drum.

Rope length (m) = (A+B) x A x C x π x 106 / d2

A, B and C are quoted in metres and d in millimetres.

Note that ropes are normally manufactured to a maximum oversize tolerance of up to 5%.

Before start working with steel wire ropes

After the rope has been installed and before it is taken into operation, several run-throughs of a normal operation cycle should be carried out under light load to let the rope adjust itself to the actual operating conditions.

![feather-weight[new]_225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11544/image-thumb__11544__general-base/feather-weight-new-_225mm_2.996762c8.png)

![feather-weight[new]_225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11544/image-thumb__11544__general-thumb/feather-weight-new-_225mm_2.3f61246f.png)

![feather-weight[new]_225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11544/image-thumb__11544__general-base/feather-weight-new-_225mm_2.996762c8.png)

Do you have any questions?

If you have any additional questions, please contact us and we will answer you.

![eye-sock [Converted]_225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11556/image-thumb__11556__product-large/eye-sock-converted-_225mm_2.0100647e.png)

![drum [new2]_225mm_Eng](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11561/image-thumb__11561__product-large/grooveprofile_drum.63290914.png)

![multiple-layers-[Converted][new]_225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11562/image-thumb__11562__product-large/multiple-layers--converted-new-_225mm_2.fa1fad14.png)

![fleetangle[new]._225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11563/image-thumb__11563__product-large/seil_5.696f37f7.png)

![feather-weight[new]_225mm_2](/sites/certex-lv/techdoc_import/Technical%20information%20general/STEEL%20WIRE%20ROPE%20PRODUCTS/Steel%20wire%20rope/Steel%20wire%20rope%20-%20handling%20and%20installation/11544/image-thumb__11544__product-large/feather-weight-new-_225mm_2.70272117.png)