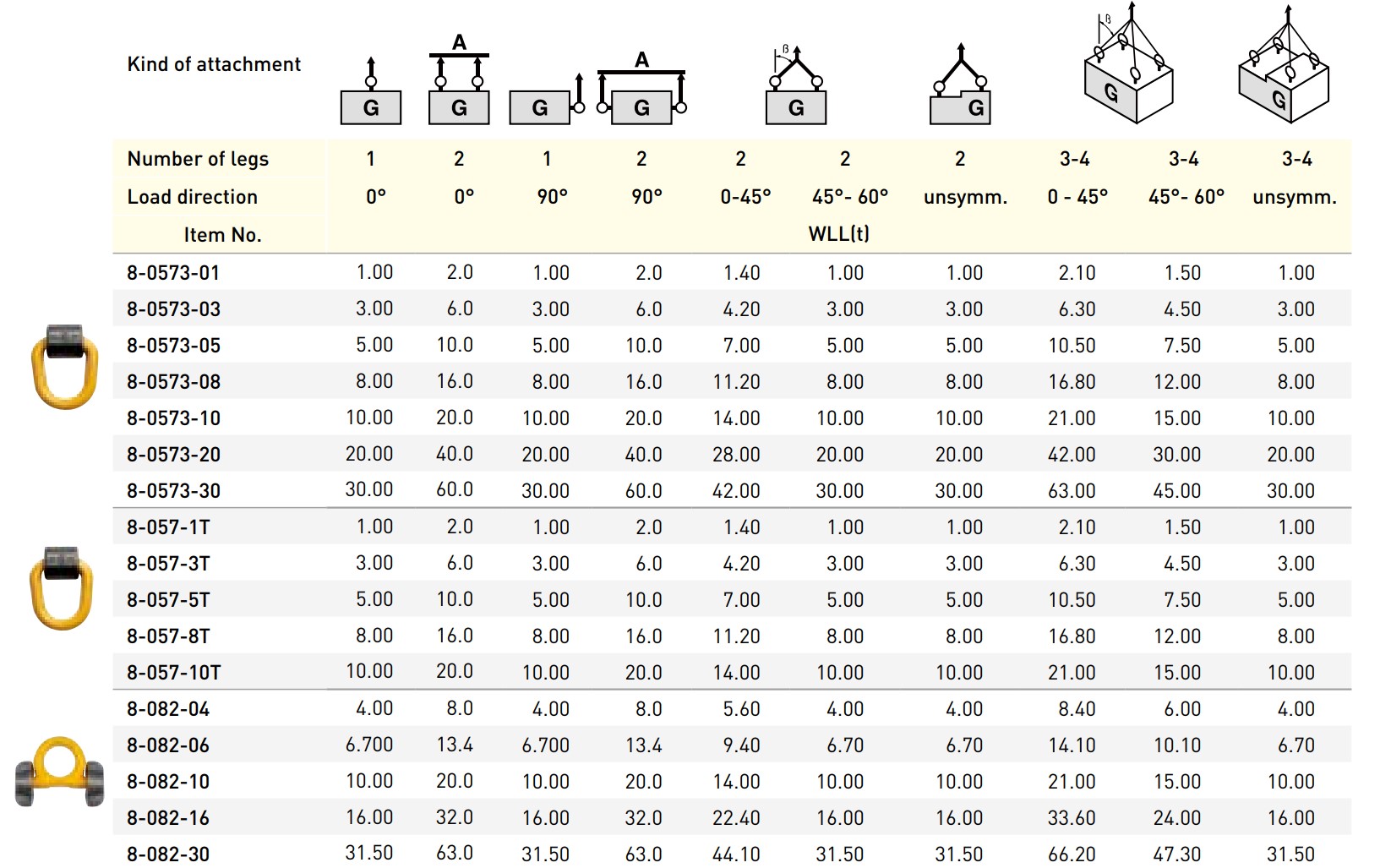

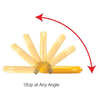

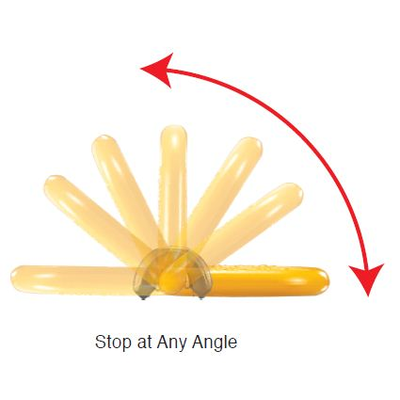

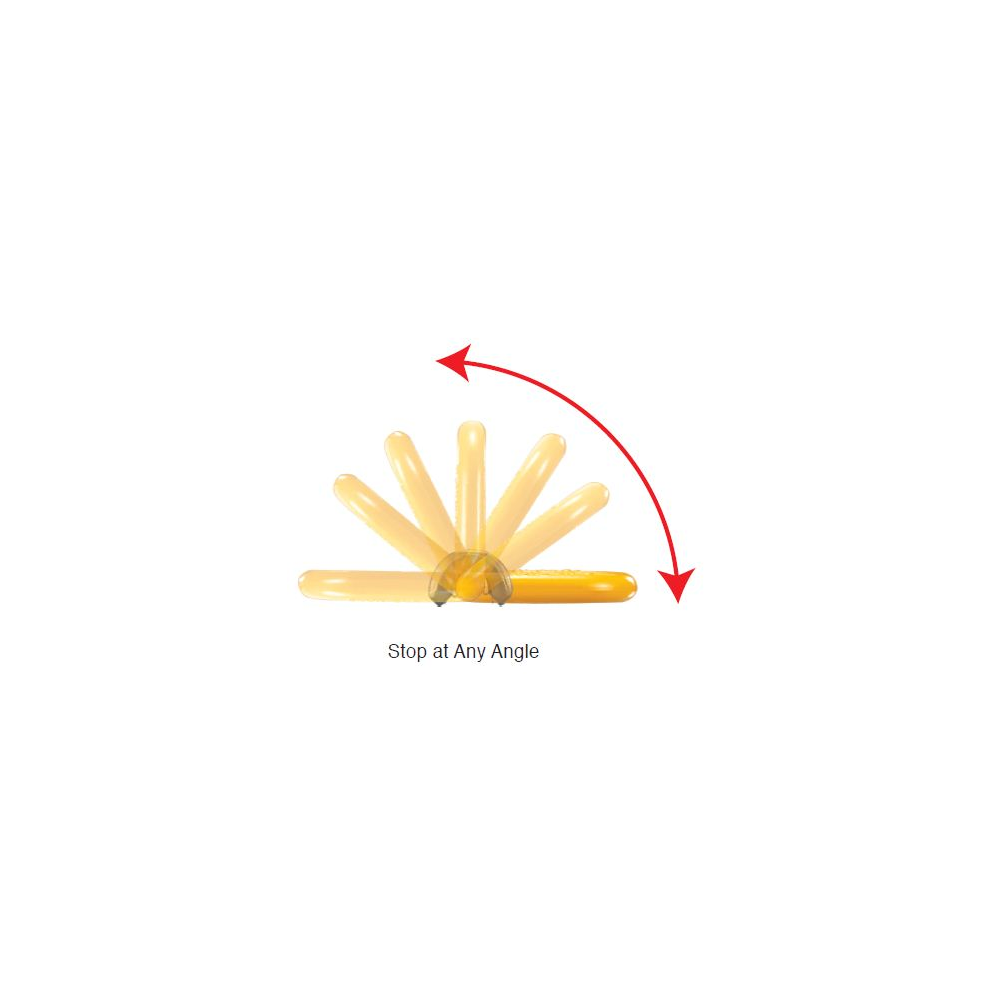

The eyes can be loaded with working load limit in all directions, pivots through 180°. Load rated parts are 100% magnaflux crack detected.

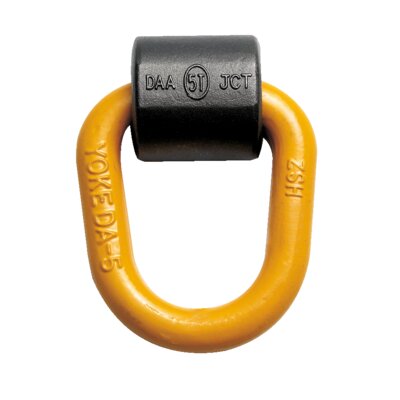

Individual forged parts are traceable to Test Certification.

Proof tested to 2.5 times the WLL, fatigue rated to 1.5 times the WLL.

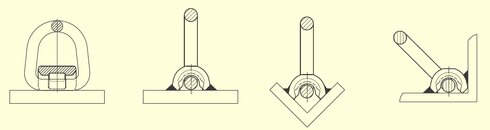

A protected spring keeps the load ring in a required position. The parts are connected in such a way that they remain captive. The spring also reduces noise caused by vibration.

- Material: Manufactured from forged alloy steel, quenched and tempered.

- Marking: According to standard, CE-marked, WLL, size, steel quality, manufacturer ID and traceability.

- Standard: EN 1677-1