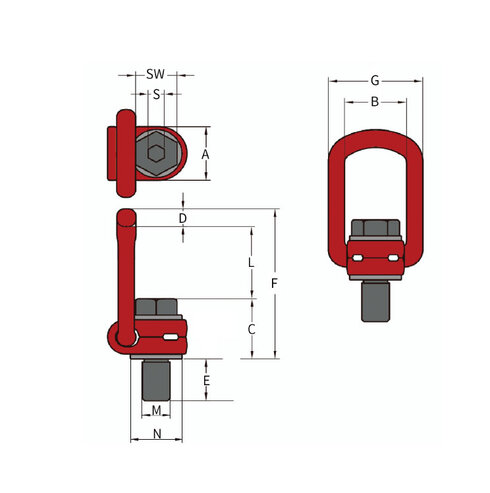

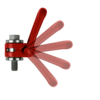

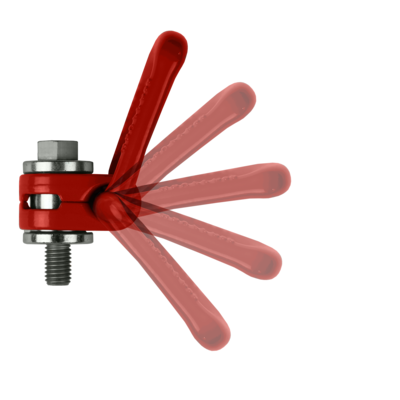

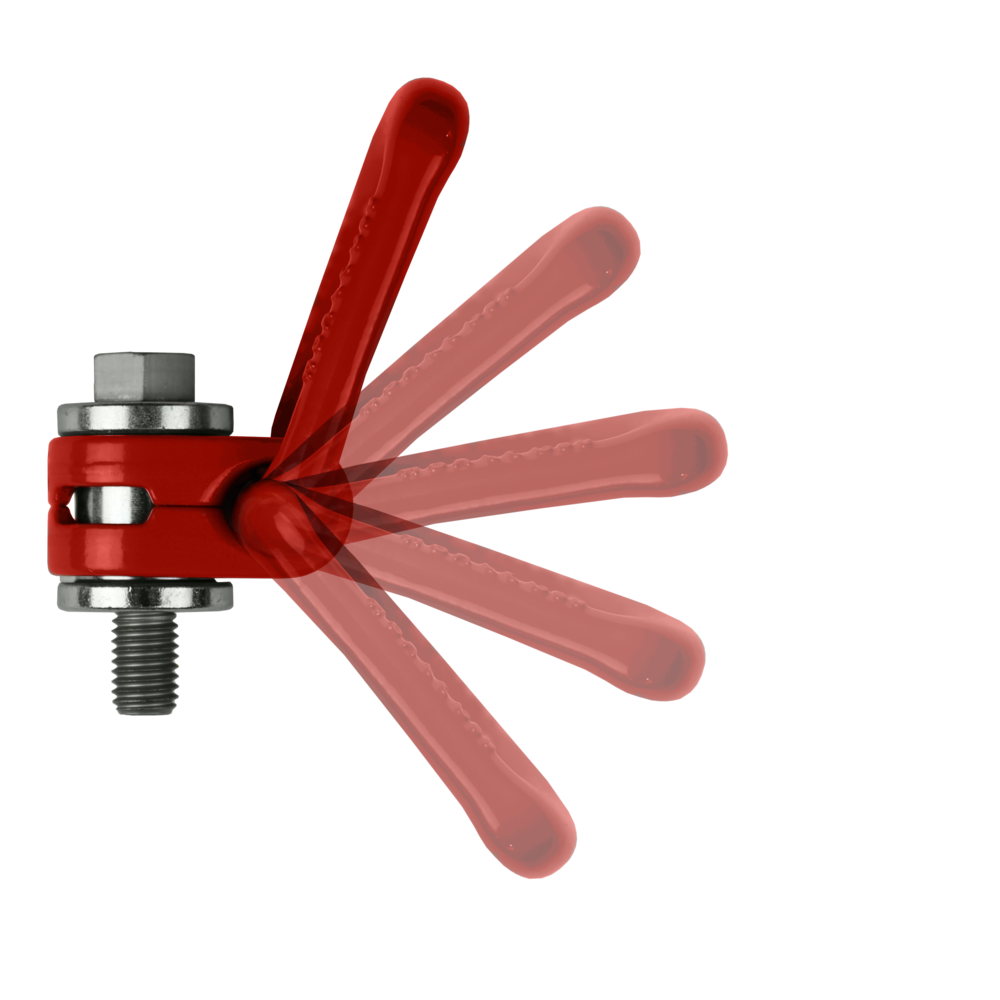

Introducing the Powertex Lifting point with a decentered link – LPD. The LPD is a robust solution for industrial environments that demand precision and durability in material handling. This lifting point is engineered to rotate 360 degrees and pivot up to 150 degrees, offering a versatile range of motion. The unique design features a forged housing with two pressed-in washers and a bolt equipped with a locking ring for secure interlocking. A spacious forged D-shaped link is securely locked within the housing opening. The bolt head is designed for versatility with an outer hexagonal grip and a hex socket cap grip, ensuring easy installation with various tools. The LPD is the quietest lifting point in the range, having a spring that removes rattling sound, making it suitable for use on vibrating machines and vehicles. The spring also allows the D-ring to be left in a vertical position. Original Powertex bolts are available in longer lengths to suit diverse requirements.

Allowed Loading directions:

- Same WLL in all directions

- 360° rotation, 150° pivot motion from vertical

- The LPD is not designed to rotate under load (choose LPB instead)

Product Features:

- Durabable finish: Coated in PURE RED powder paint, the LPD lifting points stand out for their durability and corrosion resistance.

- Compliance to standard: Manufactured to meet the testing requirements specified by EN 1677-1, ensuring high safety and quality standards.

- Reliable: Designed with a safety factor of at least 4 in the intended load directions, offering a secure lifting experience.

- Quality assurance: Each component undergoes crack detection testing in the factory and all forged links are proof load tested to ensure reliability.

- Type testing: Each model undergoes factory type testing including breaking tests and fatigue test to 20,000 cycles at 1.5 times the WLL, highlighting the product's endurance.

- Full traceability: Every component is marked with Powertex branding, model name, WLL, CE-mark, UKCA-mark, and a traceability code ensuring traceability to the production lot and raw materials.

- Uniform WLL: The LPD maintains the same WLL in all directions, simplifying load planning and increasing versatility.

- Harmless: Chromium 6 free, aligning with environmental safety standards.

- Certificates included: Comes with a Powertex 2.2 certificate & Declaration of Conformity with each box, confirming compliance with EC and UK regulations.

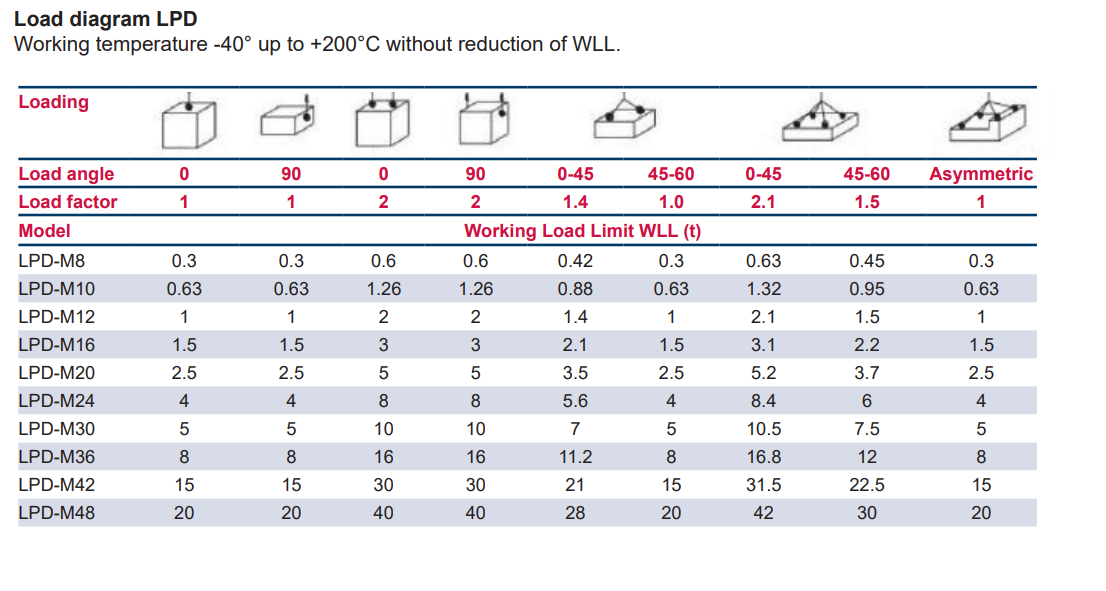

- Wide temperature range: Optimized for use between -40°C to +200°C without WLL reduction, with permissible WLL reductions for higher temperature ranges, ensuring adaptability to various environments.

- Features: 360 degrees rotatable, quiet, spacious link, longer bolts available

- Material: Forged alloy steel

- Marking: According to standard, CE-marked, UKCA-marked, Powertex, model name, WLL and batch number

- Temperature range: -40 up to +200°C without reduction in WLL

- Finish: Powder painted in PURE RED

- Standard: EN 1677-1

- Note: Before use, review the WLL diagram to select the correct LPD for your application

- Safety factor: 4:1