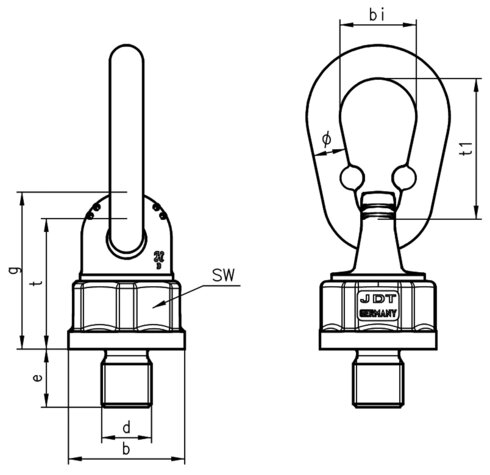

The Theipa Point lifting eye is a rotatable attachment point that can be loaded in all directions. The eye is equipped with a ball bearing swivel so that it can be rotated under load and this ensures that the eye is in the right direction when loaded.

The link can pivot and therefore also can be folded aside when not in use.

The Crimpfeature ("pinch spots") on the link prevents the link from kinking and the galvanized coating provides an optimal corrosion protection

Available on request:

- Different thread and/or lengths

- Equipped with RFID Chip

- Thread adapter: female-female or female-male

- Material: Eye and swivel of alloy steel

- Marking: CE-marked, UKCA-marked, WLL.

- Temperature range: -40° up to +400°C

- Finish: Galvanized coating - Paint

- Note: The surface that the lifting eyes shall be attatched to shall be flat and tolerate the load it is going to be exposed to.

- Safety factor: 4:1