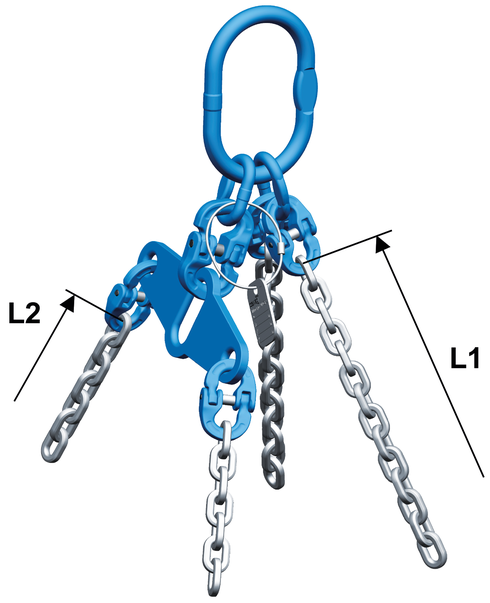

Superior weight distribution with longer lifespan. The newly developed load distributors not only conform to the requirements of a conventional load distributor, but also convince by being more effective at overall weight distribution. Due to its extremely flat design, this load distributor can be used in situations where the inclination angle is up to 60°. To improve the wear resistance of the newly developed load distributors, are produced by using Q&T steel. Should operational wear occur, the load distributor can be turned 180° – this increases the life cycle of the distributor and reduces the costs immensely. Experts value the 30% increase in carrying capacity with the same nominal diameter meaning that all four chain strands of a four-leg-sling carry the weight of the load simultaneously. Furthermore, it is possible to use a smaller dimension in order to save on weight without minimising the overall carrying capacity.

- Material: Alloy steel.

- Marking: Code, grade

- Safety factor: 4:1

- Grade: 12

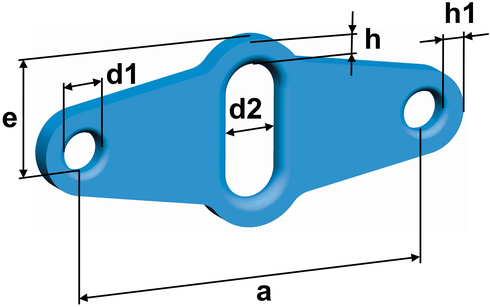

Load distributor Pewag AGWP

Load distributor Pewag AGWP

Load distributor Grade 12 with four legs

Load distributor Grade 12 with four legs

Load distributor Grade 12 with two legs

Load distributor Grade 12 with two legs

Load distributor with 4 legs

Load distributor with 4 legs

Load distributor Pewag AGWP

Load distributor Pewag AGWP

Load distributor Grade 12 with four legs

Load distributor Grade 12 with four legs

Load distributor Grade 12 with two legs

Load distributor Grade 12 with two legs

Load distributor with 4 legs

Load distributor with 4 legs